Jun . 14, 2024 06:31

Back to list

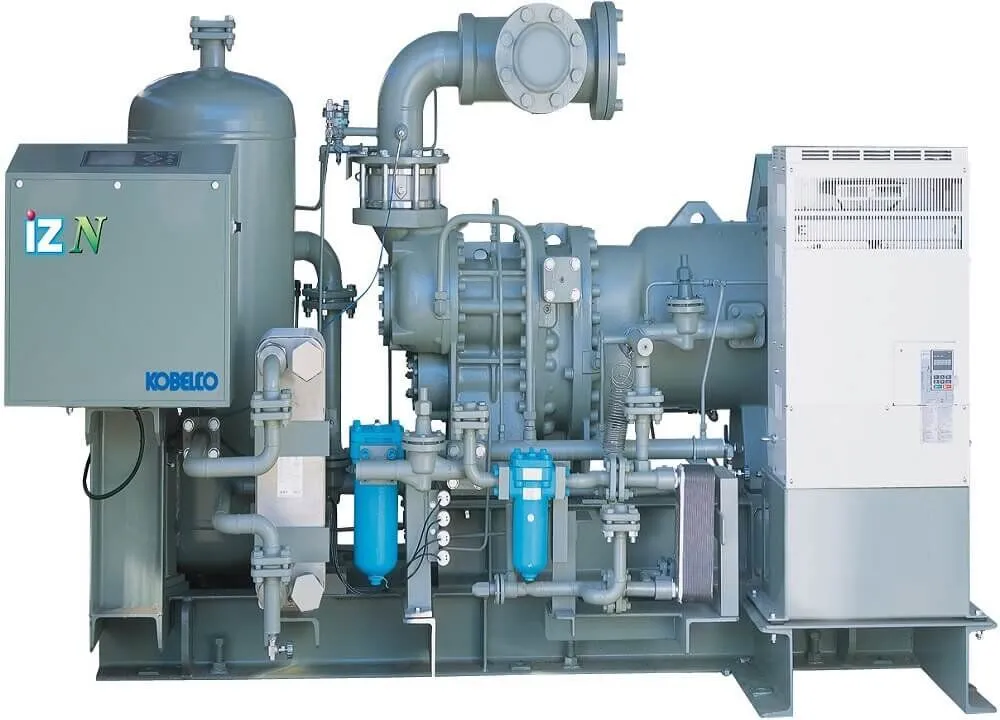

Provider of industrial chillers with compressor technology

Industrial Chiller Compressor Suppliers Key Players in the Cooling Industry

In the realm of industrial processes, efficient temperature control is paramount for optimal performance and longevity of machinery. A vital component in this regard is the industrial chiller, and at the heart of every chiller lies the compressor. This article delves into the world of industrial chiller compressor suppliers, their significance, and the factors to consider when selecting one.

Industrial chiller compressors are the workhorses that facilitate the refrigeration cycle, converting low-pressure refrigerant gas into high-pressure gas, thereby facilitating heat transfer. They come in various types, including reciprocating, screw, centrifugal, and scroll compressors, each designed for specific applications and cooling requirements.

Leading suppliers of industrial chiller compressors, such as Danfoss, Bitzer, and Carrier, have established themselves through their commitment to innovation, reliability, and energy efficiency. These companies offer a wide range of compressors tailored to meet the diverse needs of industries like plastics, pharmaceuticals, food processing, and HVAC.

Danfoss, for instance, is renowned for its advanced Scroll Compressors that provide superior part-load efficiency and a compact design. Bitzer, on the other hand, is celebrated for its robust Screw Compressors, ideal for large-scale industrial cooling systems. Carrier, a pioneer in the industry, offers a comprehensive line of centrifugal compressors, delivering high capacity and excellent part-load performance.

When choosing an industrial chiller compressor supplier, several factors must be considered. First and foremost, the supplier should be able to provide a compressor that aligns with the specific cooling demands of your process First and foremost, the supplier should be able to provide a compressor that aligns with the specific cooling demands of your process First and foremost, the supplier should be able to provide a compressor that aligns with the specific cooling demands of your process First and foremost, the supplier should be able to provide a compressor that aligns with the specific cooling demands of your process

First and foremost, the supplier should be able to provide a compressor that aligns with the specific cooling demands of your process First and foremost, the supplier should be able to provide a compressor that aligns with the specific cooling demands of your process industrial chiller compressor supplier. Energy efficiency is another critical aspect, as it directly impacts operational costs. The supplier's technical support and after-sales service are also crucial, ensuring prompt maintenance and repairs when needed.

Moreover, the supplier's reputation in the market, product quality, and compliance with industry standards and regulations should not be overlooked. It's equally important to consider their ability to customize solutions, as no two industrial processes are alike. Lastly, a supplier with a strong global presence can ensure consistent supply chain management and timely delivery.

In conclusion, industrial chiller compressor suppliers play a pivotal role in maintaining the seamless functioning of numerous industries. Their products not only ensure efficient cooling but also contribute significantly to energy savings and overall process optimization. As technology continues to advance, these suppliers will continue to innovate, pushing the boundaries of what's possible in industrial refrigeration. Whether it's a small-scale production or a massive industrial facility, the right chiller compressor supplier can make all the difference in achieving optimal performance and sustainability.

industrial chiller compressor supplier. Energy efficiency is another critical aspect, as it directly impacts operational costs. The supplier's technical support and after-sales service are also crucial, ensuring prompt maintenance and repairs when needed.

Moreover, the supplier's reputation in the market, product quality, and compliance with industry standards and regulations should not be overlooked. It's equally important to consider their ability to customize solutions, as no two industrial processes are alike. Lastly, a supplier with a strong global presence can ensure consistent supply chain management and timely delivery.

In conclusion, industrial chiller compressor suppliers play a pivotal role in maintaining the seamless functioning of numerous industries. Their products not only ensure efficient cooling but also contribute significantly to energy savings and overall process optimization. As technology continues to advance, these suppliers will continue to innovate, pushing the boundaries of what's possible in industrial refrigeration. Whether it's a small-scale production or a massive industrial facility, the right chiller compressor supplier can make all the difference in achieving optimal performance and sustainability.

First and foremost, the supplier should be able to provide a compressor that aligns with the specific cooling demands of your process First and foremost, the supplier should be able to provide a compressor that aligns with the specific cooling demands of your process

First and foremost, the supplier should be able to provide a compressor that aligns with the specific cooling demands of your process First and foremost, the supplier should be able to provide a compressor that aligns with the specific cooling demands of your process industrial chiller compressor supplier. Energy efficiency is another critical aspect, as it directly impacts operational costs. The supplier's technical support and after-sales service are also crucial, ensuring prompt maintenance and repairs when needed.

Moreover, the supplier's reputation in the market, product quality, and compliance with industry standards and regulations should not be overlooked. It's equally important to consider their ability to customize solutions, as no two industrial processes are alike. Lastly, a supplier with a strong global presence can ensure consistent supply chain management and timely delivery.

In conclusion, industrial chiller compressor suppliers play a pivotal role in maintaining the seamless functioning of numerous industries. Their products not only ensure efficient cooling but also contribute significantly to energy savings and overall process optimization. As technology continues to advance, these suppliers will continue to innovate, pushing the boundaries of what's possible in industrial refrigeration. Whether it's a small-scale production or a massive industrial facility, the right chiller compressor supplier can make all the difference in achieving optimal performance and sustainability.

industrial chiller compressor supplier. Energy efficiency is another critical aspect, as it directly impacts operational costs. The supplier's technical support and after-sales service are also crucial, ensuring prompt maintenance and repairs when needed.

Moreover, the supplier's reputation in the market, product quality, and compliance with industry standards and regulations should not be overlooked. It's equally important to consider their ability to customize solutions, as no two industrial processes are alike. Lastly, a supplier with a strong global presence can ensure consistent supply chain management and timely delivery.

In conclusion, industrial chiller compressor suppliers play a pivotal role in maintaining the seamless functioning of numerous industries. Their products not only ensure efficient cooling but also contribute significantly to energy savings and overall process optimization. As technology continues to advance, these suppliers will continue to innovate, pushing the boundaries of what's possible in industrial refrigeration. Whether it's a small-scale production or a massive industrial facility, the right chiller compressor supplier can make all the difference in achieving optimal performance and sustainability. Related PRODUCTS

Copyright © 2025 Shijiazhuang Xuexiang Refrigeration Euquipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy