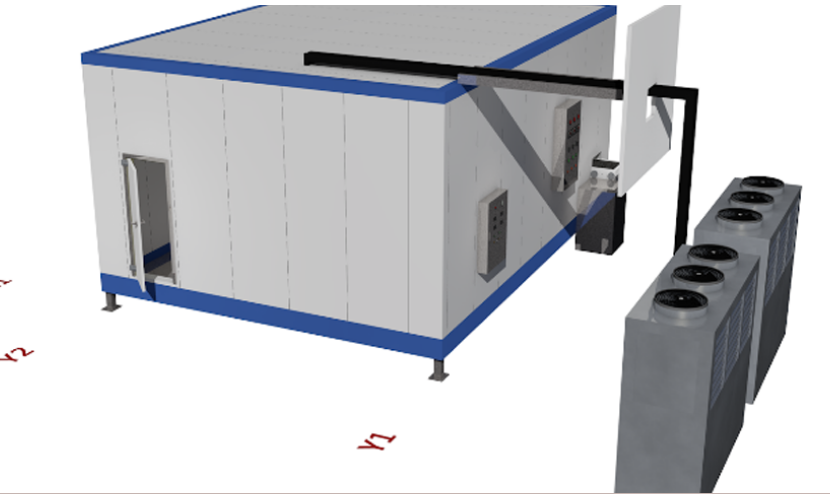

screw driven chiller factory

Exploring the World of Screw Driven Chiller Factories

In the realm of industrial refrigeration and air conditioning, screw-driven chillers have emerged as a cornerstone technology, renowned for their efficiency and reliability. As the demand for energy-efficient cooling solutions continues to rise, screw-driven chiller factories are playing a pivotal role in meeting this need. This article delves into what screw-driven chillers are, their advantages, and the significance of their manufacturing processes.

Understanding Screw Driven Chillers

Screw-driven chillers utilize rotary screw compressors, which are distinguished by their simplicity and effectiveness in compressing refrigerants. Unlike traditional chillers that use reciprocating compressors, screw chillers consist of two interlocking helical screws that continuously compress the refrigerant without the need for valves. This design provides a smooth flow and efficient operation, making it ideal for large-scale cooling applications, such as in commercial buildings, industrial processes, and district cooling systems.

The Manufacturing Process

The production of screw-driven chillers involves several critical stages, each demanding precision engineering and high-quality materials. The process typically begins with the design phase, where engineers leverage advanced software to create detailed specifications and simulations. This is followed by the fabrication of key components, such as the compressor assembly, heat exchangers, and control systems.

In modern screw-driven chiller factories, state-of-the-art machinery and automation are employed to ensure consistency and quality in every unit produced. CNC (Computer Numerical Control) machines are often used to manufacture the intricate parts with high tolerances. After assembly, rigorous testing is conducted to validate the performance and efficiency of each chiller, ensuring that they meet industry standards and client specifications.

Advantages of Screw Driven Chillers

Screw-driven chillers offer numerous benefits that make them a preferred choice for many applications. Firstly, their high efficiency translates into lower operational costs. With advancements in technology, modern screw chillers operate with Energy Efficiency Ratios (EER) that far surpass traditional systems, allowing users to achieve significant savings in energy consumption.

screw driven chiller factory

Secondly, the robust construction of screw compressors ensures durability and a long operational life. They are designed to handle varying load conditions without compromising performance, making them ideal for facilities requiring consistent cooling.

Another advantage is their ability to maintain constant cooling output even under fluctuating environmental conditions. This makes screw-driven chillers exceptionally reliable for critical applications, such as data centers and manufacturing facilities, where temperature control is paramount.

Environmental Considerations

As sustainability becomes increasingly important, screw-driven chillers also contribute to eco-friendly practices. Many manufacturers prioritize environmentally safe refrigerants in their designs to reduce greenhouse gas emissions. Furthermore, the energy efficiency of screw chillers minimizes electricity consumption, thereby reducing the overall carbon footprint of both commercial and industrial operations.

The Market Landscape

The market for screw-driven chillers is expanding rapidly, with several key players leading the industry. Companies are continuously innovating to improve performance, reduce environmental impact, and cater to the specific needs of various sectors. Increasing urbanization and industrialization in developing regions further propel the demand for advanced cooling solutions, positioning screw-driven chiller factories at the forefront of this growth.

Conclusion

Screw-driven chiller factories are indispensable in the modern landscape of refrigeration and air conditioning technologies. With their efficient operation, robust design, and commitment to sustainability, they embody the future of industrial cooling solutions. As technology continues to evolve, these factories will undoubtedly play a key role in shaping an energy-efficient and environmentally responsible future. Whether in large commercial complexes or critical manufacturing environments, screw-driven chillers stand ready to meet the challenges of contemporary cooling needs.