Efficient Cooling Solutions with Advanced Vacuum Chiller Technology for Optimal Performance

The Vacuum Chiller An Essential Innovation in Food Preservation

In the world of food preservation and processing, technology continues to evolve, offering innovative solutions that improve safety, quality, and shelf life. One such groundbreaking development is the vacuum chiller. This remarkable appliance utilizes advanced principles of thermodynamics to enhance the cooling process and address several challenges faced by food manufacturers and consumers alike.

How Vacuum Chillers Work

A vacuum chiller operates by employing reduced pressure in a controlled environment. By lowering the atmospheric pressure, the boiling point of water is decreased, allowing foods to be cooled or frozen at a much lower temperature than conventional methods. This process results in less ice crystal formation, which is crucial in maintaining the integrity and texture of delicate food items.

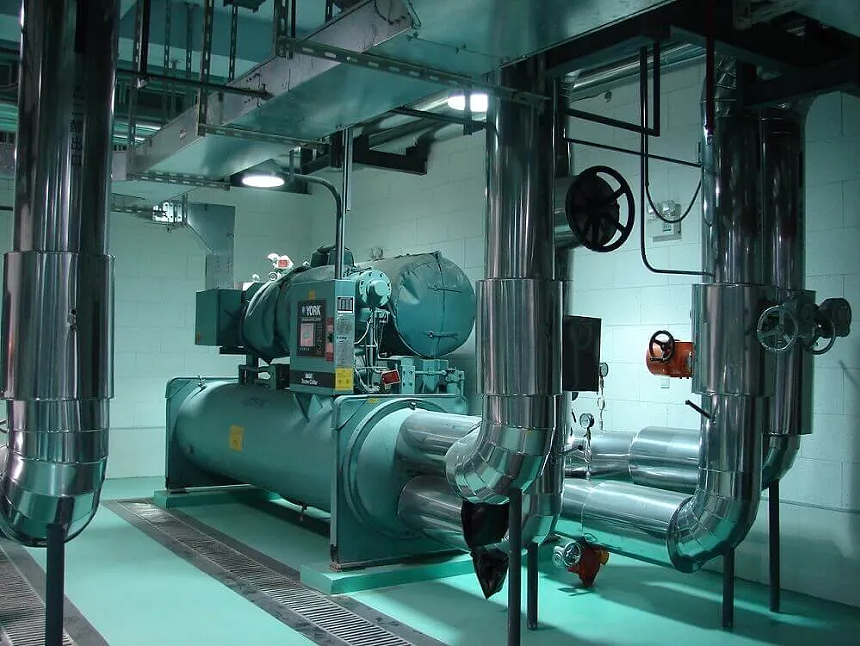

Typically, vacuum chillers feature multiple components, including vacuum pumps, heat exchangers, and insulated chambers. The food product is placed inside the insulated chamber, and the vacuum pump removes air, creating the vacuum environment. As a result, the food’s temperature drops quickly, minimizing the time it spends in the temperature danger zone where bacteria can proliferate.

Benefits of Using Vacuum Chillers

The advantages of vacuum chillers are numerous, and their implementation can greatly benefit various sectors of the food industry

.1. Improved Food Quality One of the primary benefits of vacuum chilling is the preservation of food quality. Since the cooling process occurs rapidly and at lower temperatures, the flavor, color, and nutritional value of the food are much better retained compared to traditional chilling methods. This is particularly important for high-value products such as seafood, fruits, and vegetables.

2. Extended Shelf Life By significantly slowing down enzymatic reactions and microbial growth, vacuum chillers can extend the shelf life of perishable items. This translates to reduced food waste on both the consumer and commercial levels, contributing to a more sustainable food system.

vacuum chiller

3. Energy Efficiency Vacuum chillers are designed to be energy-efficient. The rapid cooling process requires less energy compared to traditional chilling methods, which can lead to substantial cost savings for businesses. Moreover, as sustainability becomes a priority, adopting such technologies can reduce a company’s overall carbon footprint.

4. Versatility The versatility of vacuum chillers makes them suitable for various applications. They are effective not only in chilling and freezing but can also be employed in the blanching of vegetables and quick-cooling of cooked foods. This adaptability allows manufacturers to streamline their processes and improve overall productivity.

5. Enhanced Food Safety By minimizing the time food spends in the danger zone, vacuum chillers contribute significantly to food safety. Rapid cooling helps to inhibit bacterial growth, ensuring that food products are safe for consumption and compliant with health regulations.

Applications in the Food Industry

The applications of vacuum chillers are vast, finding use in food processing facilities, restaurants, and even home kitchens. Commercial seafood processing plants utilize vacuum chillers to quickly cool freshly caught fish, ensuring the highest quality product reaches consumers. Similarly, fruit and vegetable processors can maintain the freshness and crispness of their products, making them more appealing to consumers.

In restaurants, vacuum chillers can be integrated into sous-vide cooking techniques, where food is sealed in bags and cooked at precise temperatures. This enhances flavor profiles and maintains moisture content while ensuring food safety.

Conclusion

As the demand for high-quality, safe, and sustainable food products continues to rise, innovations like vacuum chillers play a transformational role in the food industry. By improving food quality, extending shelf life, and increasing energy efficiency, vacuum chillers not only enhance the processing capabilities of food manufacturers but also contribute to a safer and more sustainable food system. As technology continues to advance, the vacuum chiller will undoubtedly remain a key player in the evolution of food preservation techniques.