Efficient, Reliable Semi Hermetic Condensing Units

Introduction to Advanced Refrigeration Technology

In the demanding landscape of industrial and commercial refrigeration, selecting the appropriate condensing unit is paramount for operational efficiency, cost-effectiveness, and environmental compliance. Among the various types available, the semi hermetic condensing unit stands out as a versatile and robust solution. These units are engineered to provide reliable cooling across a wide range of temperatures, from deep freezing to medium temperature applications, making them indispensable in sectors requiring precise thermal management. Their design offers a unique balance between the sealed integrity of hermetic units and the serviceability of open-type compressors, delivering unparalleled flexibility and longevity. This article delves into the technical intricacies, operational advantages, and strategic applications of these critical components, providing B2B decision-makers and engineers with a comprehensive guide to their value proposition in optimizing industrial cold chain and process cooling infrastructures.

Current Industry Trends in Refrigeration

The industrial refrigeration sector is experiencing transformative shifts driven by global imperatives for sustainability, energy efficiency, and digitalization. Key trends influencing the development and deployment of semi hermetic condensing units include:

- Refrigerant Transition: A strong push towards refrigerants with low Global Warming Potential (GWP), such as R290 (propane), R744 (CO2), and HFO blends, is reshaping unit designs. Manufacturers are adapting compressors and systems to safely and efficiently utilize these environmentally friendly alternatives, impacting material compatibility and pressure ratings.

- Enhanced Energy Efficiency: Driven by rising energy costs and stringent regulations (e.g., European Ecodesign Directive), units are incorporating advanced technologies like variable speed drives (VSD) for compressors and fans, electronic expansion valves, and optimized heat exchanger designs. This significantly reduces operational expenses and carbon footprint.

- Smart Refrigeration and IoT Integration: The integration of Internet of Things (IoT) sensors, advanced controls, and predictive maintenance algorithms is becoming standard. This allows for real-time monitoring of system performance, remote diagnostics, optimized operation based on load demands, and proactive issue resolution, enhancing reliability and reducing downtime.

- Modularity and Customization: Industrial applications often demand tailored solutions. The trend is towards modular systems that can be easily customized to specific site requirements, offering scalability and simplified installation.

- Increased Focus on Reliability and Serviceability: In critical industrial processes, system uptime is paramount. There is an increasing demand for robust units designed for extended service life and ease of maintenance, minimizing operational interruptions.

These trends collectively underscore the evolution of refrigeration technology towards more sustainable, intelligent, and adaptable solutions, with advanced condensing units playing a pivotal role in this progression.

Manufacturing Process of a Semi Hermetic Condensing Unit

The production of a semi hermetic condensing unit is a meticulous process involving advanced engineering and stringent quality control to ensure optimal performance and longevity. Below is a detailed breakdown of the typical manufacturing flow, emphasizing critical stages, materials, and testing protocols.

Key Stages of Production:

-

Component Sourcing and Material Preparation:

High-grade materials are selected, including cast iron or high-strength steel for compressor housings, copper for piping and heat exchanger coils, and specialized alloys for internal moving parts. Raw materials undergo rigorous quality checks to meet specifications for mechanical properties, corrosion resistance, and purity, adhering to standards like ASTM A48/A48M for cast iron or ASTM A36 for structural steel. Forging processes are used for crankshafts to achieve superior strength, while precision casting is employed for cylinder blocks.

-

Compressor Assembly (Sub-assembly):

The compressor, the heart of the unit, is assembled with precision-machined components. This involves crankshafts, connecting rods, pistons, and valve plates being fitted into the compressor housing. Critical components are often produced via CNC machining to achieve micron-level tolerances, ensuring minimal friction and optimal compression efficiency. Gaskets and seals are chosen for chemical compatibility with various refrigerants and long-term elasticity.

-

Heat Exchanger Fabrication (Condenser Coil):

Copper tubes are expanded into aluminum fins using mechanical or hydraulic methods to ensure excellent thermal contact. The coil is then brazed using high-purity solder under an inert atmosphere to prevent oxidation, followed by a pressure test (e.g., 400 psi nitrogen) to detect leaks. Fin materials can be coated (e.g., epoxy, hydrophilic) for enhanced corrosion resistance, particularly important in harsh environments like marine or petrochemical facilities.

-

Unit Integration and Brazing:

The compressor, condenser coil, receiver, filter drier, and control components are mounted onto a robust base frame, typically fabricated from powder-coated steel for durability and corrosion resistance. All refrigerant lines are meticulously brazed, adhering to strict industry standards (e.g., ASME B31.5 for Refrigeration Piping), ensuring hermetic sealing and structural integrity.

-

Vacuum and Dehydration:

Post-brazing, the entire refrigerant circuit is evacuated to extremely low pressures (typically below 500 microns) to remove non-condensable gases and moisture. This critical step prevents chemical reactions, component degradation, and performance losses in the field. Multiple vacuum cycles with nitrogen breaks may be employed for thorough dehydration.

-

Leak Testing and Charging:

After evacuation, the unit undergoes a comprehensive leak test using helium mass spectrometry or similar high-sensitivity methods to detect even minute leaks, ensuring compliance with ISO 9001 quality standards. Once validated, the unit is precisely charged with the specified lubricant and a holding charge of inert gas (e.g., nitrogen) for shipment, or the designated refrigerant for factory-tested units.

-

Functional Testing and Performance Validation:

Each unit undergoes extensive functional testing under simulated operating conditions to verify compressor performance, fan operation, control logic, pressure switch settings, and overall cooling capacity. This includes pull-down tests, efficiency measurements (COP/EER), and noise/vibration analysis, ensuring compliance with design specifications and industry benchmarks like ANSI/ASHRAE 23-1993 for compressor testing.

-

Final Inspection and Packaging:

A final visual inspection checks for aesthetic quality, proper labeling, and documentation. Units are then securely packaged, often in wooden crates with desiccant packs, to prevent damage during transit to target industries such as petrochemical, metallurgy, food processing, and pharmaceutical sectors. The typical service life of a well-maintained industrial unit can exceed 15-20 years, demonstrating excellent return on investment.

In typical application scenarios, these units demonstrate significant advantages, such as energy saving through optimized component selection and control strategies, and superior corrosion resistance owing to specialized coatings and material choices for components exposed to harsh environments, particularly critical in chemical plants or coastal installations.

Technical Specifications of a Bitzer Semi-Hermetic Open-Type Condensing Unit

The Bitzer Semi-Hermetic Open-type Condensing Unit, designed for a broad temperature range of -45℃ to +5℃, exemplifies cutting-edge refrigeration technology. Its design combines the robustness and serviceability of a semi-hermetic compressor with the flexibility of an open-type configuration, making it adaptable for various medium to low-temperature applications. Understanding its parameters is crucial for optimal system integration, confirming the efficacy of a semi hermetic condensing unit.

Bitzer Semi-Hermetic Condensing Unit Key Specifications

| Parameter | Description/Value |

|---|---|

| Compressor Type | Bitzer Semi-Hermetic Piston Compressor (e.g., 2-stage or single-stage depending on model) |

| Operating Temperature Range | -45°C to +5°C Evaporating Temperature (Low to Medium Temperature Applications) |

| Refrigerant Compatibility | R404A, R507A, R448A, R449A, R407F, R134a (depending on model variant) |

| Cooling Capacity Range | Typically from 5 kW to 150 kW+ (variable by compressor model and operating conditions) |

| Power Supply | 3 Phase, 380V-420V/50Hz; 460V/60Hz (configurable) |

| Condenser Type | Air-cooled fin-and-tube or Water-cooled shell-and-tube |

| Fan Type (Air-cooled) | Axial flow fans, low noise, high efficiency, IP54 rated motors |

| Control System | Microprocessor-based controller, high/low pressure switches, oil pressure differential switch, phase sequence relay, overload protection. Optional: VSD, IoT integration. |

| Receiver Volume | Optimized for system charge, with liquid line service valve, relief valve. |

| Noise Level | Typically 65-80 dB(A) at 1 meter (varies by size and operating conditions) |

| Dimensions (L x W x H) | Variable depending on model and capacity (e.g., 2000x1000x1500mm for a mid-range unit) |

| Weight | Variable depending on model and capacity (e.g., 500-1500 kg) |

| Certifications | CE, PED, RoHS compliant, ISO 9001, ISO 14001 manufacturing standards |

These specifications highlight the robust engineering and versatility that make Bitzer units a preferred choice for demanding refrigeration applications. The range of compatible refrigerants and adaptable power supplies ensures suitability for diverse global markets and specific environmental mandates.

Diverse Application Scenarios

The inherent flexibility and broad operating range of the semi hermetic condensing unit make it suitable for a multitude of industrial and commercial refrigeration applications. Unlike fully hermetic units, which are sealed and offer limited serviceability, semi-hermetic units provide the benefit of on-site maintenance and component replacement, extending their operational life and reducing long-term costs.

- Cold Storage Warehouses: Essential for maintaining precise temperatures in large-scale cold rooms and freezers used for food preservation, pharmaceuticals, and sensitive chemicals. The units can handle varying loads and demanding conditions of large-volume storage.

- Food Processing and Blast Freezing: In food processing plants, these units are critical for rapid chilling and blast freezing applications, where quick temperature pulldown is required to maintain food quality and safety, such as in meat processing, dairy production, and frozen food manufacturing.

- Supermarkets and Hypermarkets: Powering large-scale display cases, walk-in coolers, and freezer rooms. Centralized condensing units provide robust and efficient cooling for extensive retail refrigeration architectures.

- Pharmaceutical and Medical Storage: Maintaining strict temperature controls for vaccines, biologics, and other temperature-sensitive medical supplies, where even slight deviations can compromise product integrity. These units offer the reliability required for such critical applications.

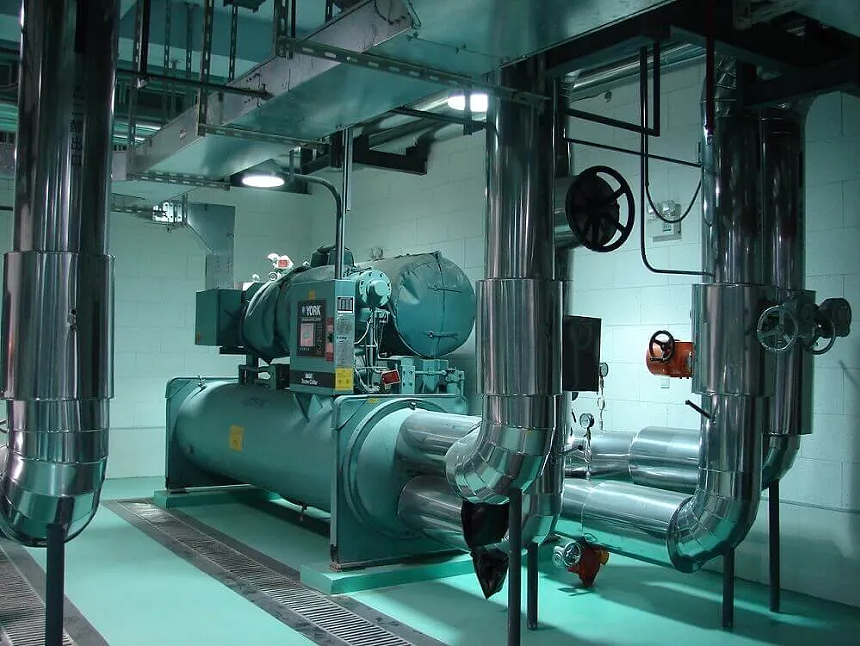

- Industrial Process Cooling: Providing cooling for various industrial processes in sectors like petrochemicals, plastics manufacturing, and metalworking, where heat removal is integral to production efficiency and product quality. Their durability makes them ideal for challenging industrial environments.

- Chemical and Petrochemical Industries: In these environments, the robustness and adaptability to various refrigerants, including natural refrigerants, along with enhanced corrosion resistance (often achieved through specialized coil coatings and stainless steel components), make them a preferred choice for cooling process streams or storage facilities.

- Ice Production Plants: From flake ice to block ice, these units provide the consistent and powerful refrigeration needed for efficient ice manufacturing operations.

The capability to operate across a wide temperature spectrum and with diverse refrigerants allows a single unit model to serve multiple functions, streamlining inventory and maintenance for large-scale operators.

Technical Advantages of Semi-Hermetic Condensing Units

The design philosophy behind the semi hermetic condensing unit offers distinct technical advantages over other compressor types, particularly in industrial and heavy commercial applications where reliability, flexibility, and serviceability are paramount.

- Superior Serviceability and Maintainability: Unlike fully hermetic condensing units, which are sealed and often require complete replacement upon failure, semi-hermetic compressors allow for on-site access to internal components (e.g., motor, valves, pistons). This significantly reduces downtime and repair costs, extending the overall service life of the unit and offering a lower Total Cost of Ownership (TCO).

- Enhanced Energy Efficiency: Modern semi-hermetic units, especially those from leading manufacturers like Bitzer, incorporate advanced technologies such as electronic expansion valves, intelligent controls, and variable capacity mechanisms (e.g., cylinder deactivation or VSDs). These features optimize performance across varying load conditions, leading to substantial energy savings compared to fixed-capacity systems.

- Broad Refrigerant Compatibility: The design allows for a wider range of refrigerants, including newer, low-GWP options (e.g., R290, R744, R448A, R449A). This flexibility future-proofs installations against evolving environmental regulations and provides options for specific application requirements or geographical compliance.

- Robust Construction for Demanding Conditions: Built with heavy-duty components and durable materials, these units are designed to withstand the rigors of continuous industrial operation. Their robust build ensures long-term reliability even in challenging environments, such as those with high ambient temperatures or fluctuating electrical supply.

- Flexible Capacity Control: Many semi-hermetic compressors feature options for capacity control, such as cylinder deactivation or integration with variable frequency drives (VFDs). This enables the unit to precisely match cooling demand, preventing short cycling, improving temperature stability, and further enhancing energy efficiency.

- Lower Noise and Vibration: Advanced compressor designs, combined with effective vibration isolation and sound dampening materials in the condensing unit assembly, contribute to lower operational noise levels. This is a significant advantage in urban environments or facilities where noise pollution is a concern.

These technical advantages translate directly into operational benefits for B2B clients, including reduced operational costs, increased system uptime, and greater adaptability to future market demands.

Vendor Comparison: Bitzer Semi-Hermetic vs. Other Solutions

When investing in a semi hermetic condensing unit, discerning buyers evaluate options based on performance, reliability, efficiency, and support. While Bitzer is a global leader, it's beneficial to understand how its offerings compare to other prominent manufacturers or alternative refrigeration technologies. This comparison focuses on critical criteria for B2B decision-makers.

Comparison Table: Semi-Hermetic Condensing Units

| Feature/Criteria | Bitzer Semi-Hermetic Units | Competitor A (e.g., Carrier/Copeland) | Fully Hermetic Units (General) |

|---|---|---|---|

| Compressor Type | Piston (Reciprocating), Screw | Piston, Scroll, Screw | Piston, Scroll, Rotary |

| Serviceability | Excellent (field repairable, component replacement) | Good (some models field serviceable) | Limited (often unit replacement) |

| Energy Efficiency (EER/COP) | High (with advanced controls, VSD options) | High (competitive with similar features) | Moderate to High (best in smaller capacities) |

| Refrigerant Versatility | Very High (optimized for diverse HFCs, HFOs, Naturals) | High (supports most common refrigerants) | Moderate (specific models for specific refrigerants) |

| Application Range | Wide (low, medium, high temp; industrial/commercial) | Wide (similar, strong in specific niches) | Narrow (small commercial, residential, specific plug-ins) |

| Initial Cost | Moderate to High | Moderate to High | Low to Moderate |

| Lifespan/Durability | Excellent (15-20+ years with proper maintenance) | Excellent (similar longevity) | Moderate (5-10 years, replacement typical) |

| Global Support Network | Extensive (strong global presence) | Extensive (strong global presence) | Varies by manufacturer, generally localized |

Bitzer semi-hermetic units consistently rank high in all critical areas, particularly in serviceability and refrigerant versatility, which are crucial for long-term industrial investments. While the initial investment might be higher than fully hermetic alternatives, the significantly extended lifespan, lower maintenance costs, and superior performance efficiency often lead to a more favorable TCO over the operational life. Furthermore, their robust design and broad application capabilities minimize risks in diverse industrial settings.

Customized Solutions for Unique Demands

Recognizing that off-the-shelf solutions rarely fit all industrial requirements, providers of semi hermetic condensing units, especially those catering to specialized B2B markets, emphasize customized solutions. This approach ensures that the refrigeration system is perfectly aligned with the client's operational parameters, environmental conditions, and strategic objectives.

Customization can involve several aspects:

- Refrigerant Optimization: Tailoring the unit for specific low-GWP refrigerants (e.g., CO2 for transcritical or subcritical applications, ammonia for large industrial plants) to meet regional regulations or achieve specific energy efficiency targets.

- Capacity Modulation: Implementing precise capacity control mechanisms, such as multiple compressors, variable speed drives (VSDs), or cylinder deactivation, to efficiently match fluctuating cooling loads. This is crucial for energy savings in processes with dynamic thermal demands.

- Environmental Adaptation: Designing units for extreme ambient conditions, whether it's scorching deserts or freezing arctic regions. This might involve specialized condenser coil coatings for corrosion resistance in coastal or chemical environments, or enhanced insulation and heating elements for low-temperature operation.

- Acoustic Management: For installations in noise-sensitive areas, customized sound attenuation measures, including acoustic enclosures and low-noise fan designs, can significantly reduce operational sound levels.

- Integration with Existing Systems: Providing units designed to seamlessly integrate with existing Building Management Systems (BMS) or process control networks, offering remote monitoring, diagnostics, and operational adjustments. This ensures cohesive system operation and maximizes automation.

- Footprint and Configuration: Designing compact units for space-constrained installations or modular configurations for ease of expansion and maintenance in large industrial complexes.

Engaging with a reputable manufacturer and their engineering team allows clients to leverage their expertise to develop a truly bespoke solution that delivers optimized performance, minimizes operational risks, and maximizes return on investment.

Application Case Studies & Client Success

The proven reliability and adaptability of semi-hermetic condensing units are best illustrated through real-world applications and the positive feedback from clients. These case studies highlight their operational efficiency and robustness in demanding industrial environments.

Case Study 1: Large-Scale Food Processing Plant

A major poultry processing facility required an upgrade to its blast freezing tunnels and cold storage rooms. Their existing equipment, composed of older fully hermetic units, frequently failed under peak load conditions, leading to significant product loss and operational inefficiencies. We installed a centralized system featuring four Bitzer semi-hermetic condensing units (model range -40°C evaporating) with VSD-equipped compressors and R449A refrigerant.

- Outcome: The new system delivered a 30% reduction in energy consumption due to precise capacity control and high-efficiency compressors. Downtime for maintenance decreased by 70% as common issues could be addressed on-site without unit replacement. Product spoilage was virtually eliminated, leading to an estimated annual saving of over $250,000. Customer feedback highlighted the exceptional reliability and responsive technical support.

Case Study 2: Pharmaceutical Cold Chain Logistics Hub

A pharmaceutical distribution center needed to ensure ultra-low temperature integrity (-25°C to -35°C) for sensitive vaccines and biologics across a 5,000 square meter storage facility. The critical nature of their products demanded redundancy and continuous operation. We deployed a cascade refrigeration system utilizing Bitzer semi-hermetic condensing units in both high and low stages, employing R404A in the high stage and R507A in the low stage, with automated switchover capabilities.

- Outcome: The system achieved and consistently maintained the required ultra-low temperatures with minimal fluctuations (±0.5°C). The semi-hermetic design allowed for scheduled preventive maintenance without disrupting operations, ensuring full compliance with stringent FDA and WHO guidelines for pharmaceutical storage. The client praised the robust build quality and the peace of mind provided by the system's inherent redundancy.

Ensuring Trustworthiness: FAQs, Lead Time, Warranty & Support

Building trust with B2B clients extends beyond product specifications. It encompasses transparency in operations, clear commitments, and reliable post-sales support.

Frequently Asked Questions (FAQs)

- Q: What is the primary difference between a semi-hermetic condensing unit and a fully hermetic unit?

- A: A fully hermetic unit has a sealed compressor, making it unserviceable on-site. If it fails, the entire compressor is typically replaced. A semi-hermetic unit, however, has a bolted housing, allowing access to internal components like the motor or valve plates for repair and maintenance, offering significantly longer service life and lower lifetime costs.

- Q: Can these units operate with natural refrigerants like R290 (Propane) or R744 (CO2)?

- A: Yes, many modern semi-hermetic unit models are specifically designed and optimized for natural refrigerants, offering excellent efficiency and environmental benefits. It's crucial to select the correct model tailored for the specific refrigerant.

- Q: What is the expected service life of a Bitzer semi-hermetic condensing unit?

- A: With proper installation and routine preventive maintenance, a Bitzer semi-hermetic unit can reliably operate for 15-20 years or more, offering a long-term return on investment.

- Q: Are these units suitable for outdoor installation in harsh climates?

- A: Yes, units can be specified with robust enclosures, corrosion-resistant coatings, and weatherproofing to ensure reliable operation in diverse outdoor conditions, from extreme heat to sub-zero temperatures. Specific model selection and optional features are vital.

Lead Time & Fulfillment

Standard semi-hermetic condensing unit configurations typically have a lead time of 4-6 weeks from order confirmation, depending on current stock levels and manufacturing schedules. Custom-engineered solutions, due to their unique design and component sourcing, may require 8-12 weeks. We maintain a transparent communication channel throughout the order fulfillment process, providing regular updates on production status and estimated delivery dates. Expedited options may be available upon request and project feasibility assessment.

Warranty Commitments

All semi-hermetic condensing units are backed by a comprehensive 12-month warranty on parts and factory workmanship from the date of commissioning or 18 months from the date of shipment, whichever comes first. Extended warranty options are available for critical installations, offering enhanced peace of mind. Our warranty covers manufacturing defects and material failures under normal operating conditions, ensuring your investment is protected.

Customer Support & After-Sales Service

Our commitment extends far beyond the sale. We provide robust after-sales support, including:

- Technical Assistance: A dedicated team of experienced engineers offers remote and on-site technical support for troubleshooting, system optimization, and operational guidance.

- Spare Parts Availability: A readily available inventory of genuine Bitzer spare parts ensures minimal downtime during maintenance or repairs.

- Preventive Maintenance Programs: Tailored service contracts designed to maximize unit efficiency, extend lifespan, and prevent unforeseen breakdowns.

- Training: Comprehensive training programs for client's technical staff on operation, maintenance, and basic troubleshooting of the refrigeration system.

Our global network of authorized service partners ensures that expert assistance is always within reach, guaranteeing the continued optimal performance of your refrigeration systems.

Conclusion

The semi-hermetic condensing unit represents a cornerstone of modern industrial and commercial refrigeration. Its unique blend of robust design, superior serviceability, energy efficiency, and adaptability to diverse refrigerants and challenging environmental conditions positions it as an ideal choice for B2B applications demanding unwavering performance and long-term cost-effectiveness. By understanding the intricate manufacturing processes, technical advantages, and comprehensive support structures, decision-makers can confidently invest in solutions that not only meet current operational needs but also align with future sustainability goals and technological advancements. The commitment to quality, backed by rigorous testing and extensive after-sales support, ensures that these units deliver consistent, reliable, and efficient cooling for years to come, solidifying their role as a critical asset in any cold chain or process cooling infrastructure.

References

- ASHRAE Handbook - Refrigeration (various editions). American Society of Heating, Refrigerating and Air-Conditioning Engineers.

- Bitzer SE Official Technical Documentation and Product Catalogs.

- ISO 9001:2015 - Quality management systems – Requirements. International Organization for Standardization.

- European Commission Ecodesign Directive for Refrigerating Appliances.

- ASTM International Standards for Materials and Testing.