Air Handling Unit Compressor Manufacturing Processes and Industry Insights

Understanding Air Handling Unit Compressors A Guide to Factories and Their Significance

An air handling unit (AHU) plays a pivotal role in the heating, ventilation, and air conditioning (HVAC) systems within buildings. It is responsible for circulating air and maintaining indoor air quality. A significant component of many AHUs is the air handling unit compressor. This article offers a comprehensive overview of AHU compressors, the factories that manufacture them, and the importance of these components in modern HVAC systems.

What is an Air Handling Unit Compressor?

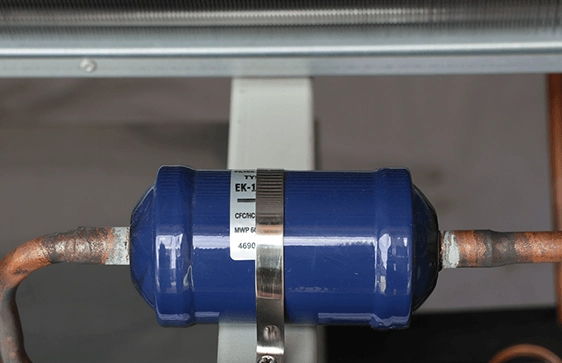

An air handling unit compressor is an essential piece of equipment that compresses refrigerant in the HVAC system, thereby reducing its volume and increasing its pressure. This process allows for efficient heat transfer, which is crucial for maintaining comfortable indoor temperatures. Compressors are typically paired with cooling and heating coils, fans, and filters, creating a system that delivers conditioned air to the building.

There are different types of compressors used in AHUs, including reciprocating, scroll, screw, and centrifugal compressors. Each type has its advantages and is chosen based on the specific needs of the HVAC system, including efficiency, capacity, and application requirements.

The Importance of Compressor Factories

Factories that produce AHU compressors play a critical role in the HVAC industry. They are responsible for designing, manufacturing, and testing these complex machines to ensure they meet high standards of efficiency and performance. The manufacturing process involves several key steps

1. Design and Engineering Engineers design compressors to optimize airflow and refrigerant handling. They also consider factors such as energy efficiency, durability, and cost-effectiveness.

2. Material Selection High-quality materials are chosen to withstand the rigors of operation. Common materials include aluminum and steel for structural components, while specialized seals and gaskets prevent refrigerant leaks.

3. Manufacturing Process Using advanced technology and machinery, manufacturers create the various components of the compressor. This can involve processes such as machining, welding, and assembly.

air handling unit compressor factories

4. Testing and Quality Assurance Before a compressor is sent to market, it undergoes rigorous testing to ensure it meets performance and safety standards. This includes checks for refrigerant leaks, energy efficiency ratings, and operational performance under different conditions.

5. Research and Development Leading manufacturers invest heavily in R&D to stay competitive. This includes the exploration of new technologies like variable speed drives, which allow compressors to operate more efficiently by adjusting their speed based on the cooling load.

The Global Landscape of Compressor Manufacturing

The market for AHU compressors is growing globally, driven by increasing demand for energy-efficient building systems and modernization of infrastructure. Factories are often located strategically around the globe to meet the needs of regional markets. Countries like the United States, Germany, and Japan are home to some of the largest and most advanced compressor manufacturing facilities.

Moreover, as sustainability becomes a priority in the HVAC industry, manufacturers are adapting by creating compressors that use eco-friendly refrigerants and improving their energy efficiency. This trend is bolstered by regulatory standards aimed at reducing greenhouse gas emissions.

Challenges Facing Compressor Factories

While the future looks promising, compressor factories face several challenges. The competition is fierce, with numerous companies vying for market share. Additionally, supply chain disruptions, particularly in recent years, have affected the availability of critical components and raw materials. Furthermore, factories must stay ahead of technological advancements and continuously innovate to meet evolving customer demands.

There’s also the necessity for skilled labor in manufacturing and maintaining advanced compressor systems. Factories are investing in workforce training programs to ensure their employees are equipped with the skills needed to operate and innovate in high-tech environments.

Conclusion

In summary, air handling unit compressors are essential to modern HVAC systems, and the factories that produce them play a crucial role in ensuring their efficiency and reliability. As the demand for intelligent and sustainable building solutions rises, these factories will continue to innovate and adapt. Understanding their importance not only sheds light on the complexities of HVAC systems but also highlights the essential role of manufacturers in building a better, more efficient future. As technology progresses, it will be fascinating to witness how these factories evolve in response to consumer needs and environmental challenges.