Compressor Solutions for Ice Cream Machine Manufacturing Facilities

Understanding Compressors for Ice Cream Machine Factories

In the world of ice cream production, the quality of the final product largely depends on the efficiency and performance of the machines involved. Among these machines, the compressor plays a crucial role. Ice cream machines utilize compressors to regulate the temperature and consistency of the mix, ensuring that the end product is creamy and smooth. This article explores the significance of compressors in ice cream machine factories, the types available, and their operational mechanics.

The Role of Compressors in Ice Cream Machines

Compressors are vital components in refrigeration systems, which are integral to ice cream-making machines. Their primary function is to compress refrigerant gas, subsequently enabling it to cycle through the condenser and evaporator coils. This process cools the mixture of ingredients that is essential for making ice cream. When the mixture is churned while it's frozen, air is incorporated, enhancing the texture. A high-quality compressor ensures that the mix maintains a consistent temperature, resulting in a uniform product free from ice crystals.

Proper cooling is essential because the freezing process needs to happen quickly to prevent large ice crystals from forming, as these can ruin the texture of the ice cream. Therefore, a responsive and powerful compressor is vital for operational efficiency.

Types of Compressors

There are several types of compressors that are commonly used in ice cream machine factories

1. Reciprocating Compressors These are the most widely used compressors in the food industry. They operate using a piston-driven mechanism, which compresses the refrigerant gas. Known for their simplicity and reliability, reciprocating compressors are ideal for small to medium-sized ice cream production.

2. Scroll Compressors Scroll compressors use a pair of spiral-shaped scrolls to compress the refrigerant. They are quieter and more efficient than reciprocating compressors and are often utilized in larger production setups. Their ability to provide a more consistent cooling solution makes them a preferred choice for manufacturers focused on high-quality output.

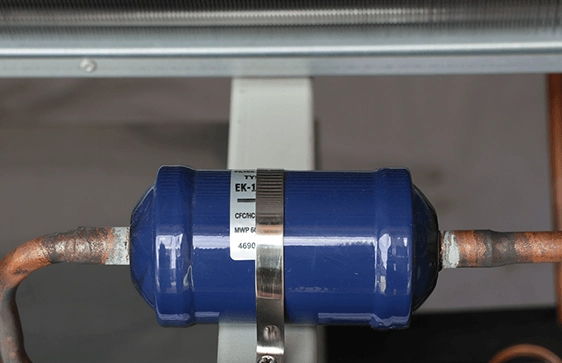

compressor for ice cream machine factories

3. Screw Compressors These are typically found in large-scale industrial ice cream production facilities. Screw compressors can handle higher volumes of refrigerant and provide excellent efficiency, making them suitable for continuous operation in high-demand environments.

4. Centrifugal Compressors While not as common in ice cream production due to their complexity and cost, centrifugal compressors can efficiently handle large capacities. They utilize a rotating impeller to compress the refrigerant and are generally used in very large installations.

Selecting the Right Compressor

Choosing the appropriate type of compressor for an ice cream machine factory depends on various factors, including production volume, the specific characteristics of the ice cream being produced, and energy efficiency. High-quality compressors not only ensure steady and efficient operations but also minimize downtime and maintenance costs.

When selecting a compressor, it's crucial for manufacturers to consider energy consumption. Energy-efficient models can significantly reduce operational costs in the long run, despite potentially higher initial investments. Additionally, many modern compressors are designed with advanced technology that enables them to adjust their output based on load demand, further optimizing energy use.

Maintenance and Longevity

A well-maintained compressor can last for many years, providing reliable performance. Regular maintenance practices, such as checking refrigerant levels, cleaning filters, and inspecting belts, are vital to prevent breakdowns and ensure optimal performance. Implementing a routine maintenance schedule can enhance the lifespan of compressors and maintain the quality of ice cream production.

Conclusion

In conclusion, compressors are a pivotal element in ice cream machine factories, directly influencing the quality and efficiency of ice cream production. Understanding the various types of compressors, their operational mechanisms, and the importance of proper maintenance can help manufacturers make informed decisions that enhance production capabilities. As technology continues to evolve, selecting the right compressor will become increasingly vital in ensuring high-quality ice cream that delights consumers while maintaining an eco-friendly footprint. Overall, the compressor's role is as fundamental in the ice cream production process as the ingredients themselves.