screw type water chiller factory

The Screw Type Water Chiller Factory Innovation in Cooling Technology

In the contemporary world, efficient cooling systems have become paramount in various industries, from manufacturing to commercial businesses. Among the most popular and increasingly vital cooling systems is the screw type water chiller. This article explores the importance of screw type water chillers, their manufacturing process at the factory level, and their impact on energy efficiency and operational costs.

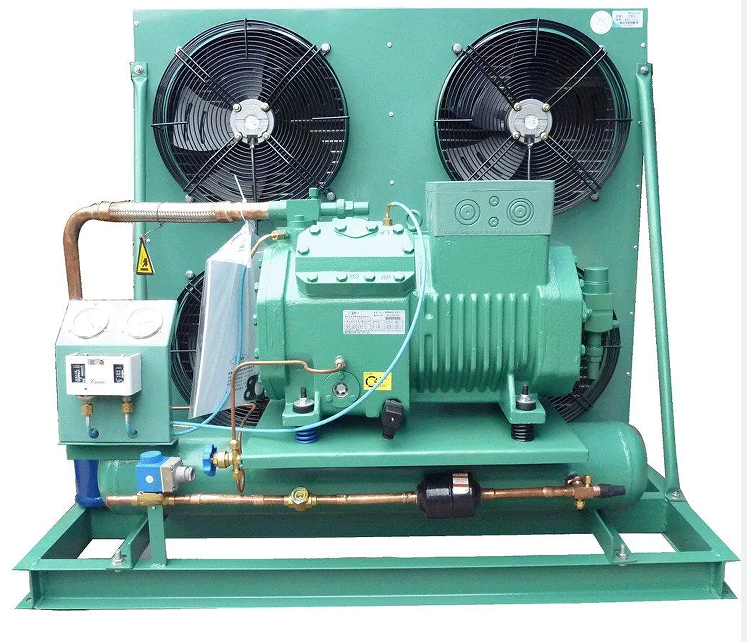

A screw type water chiller operates on the principle of vapor compression, using dual rotors to compress refrigerant gas. This type of chiller is known for its high efficiency and reliability, making it a preferred choice in large-scale applications. Factories producing these chillers focus on integrating advanced technology and engineering expertise to ensure that each unit delivers optimal performance and durability.

The process of manufacturing screw type water chillers begins with the selection of high-quality materials. The compressors, evaporators, and condensers are crafted using robust materials that can withstand various temperatures and pressures. This attention to material selection ensures that the chillers can perform efficiently in demanding environments.

Once the materials are procured, the next step involves the precision engineering of components. This stage requires state-of-the-art machinery and skilled technicians who understand the intricacies of the design. Accurate manufacturing is crucial because even the slightest deviation can lead to inefficiencies or mechanical failures. Factories often utilize computer-aided design (CAD) software to simulate and optimize components before they are produced.

screw type water chiller factory

After components are manufactured, they undergo rigorous testing to ensure they meet industry standards and specifications. This quality assurance process is vital for maintaining the reliability of screw type water chillers. Tests typically include operational checks under simulated conditions to examine the performance of each chiller. Only after passing these rigorous tests will the chillers be assembled and prepared for distribution.

One of the significant advantages of screw type water chillers is their energy efficiency. In contrast to other chiller types, screw chillers often consume less power, leading to lower operational costs. Additionally, many factories that produce screw type water chillers strive to incorporate environmentally friendly refrigerants, reducing their environmental footprint. This commitment to energy efficiency and sustainability is essential in today’s eco-conscious marketplace.

Furthermore, the versatility of screw type water chillers allows them to cater to various applications, from industrial processes to HVAC systems in commercial buildings. Their ability to handle large cooling loads while maintaining efficiency makes them an attractive option for businesses looking to optimize their energy consumption and reduce overall costs.

In conclusion, the screw type water chiller factory plays a crucial role in the development of advanced cooling technologies. By focusing on high-quality materials, precision engineering, and rigorous testing, these factories create reliable and efficient cooling systems. As industries increasingly prioritize energy efficiency and sustainability, screw type water chillers stand out as an essential solution for modern cooling needs.