oem small industrial chiller

Understanding OEM Small Industrial Chillers Efficiency and Customization

In the modern industrial landscape, the demand for effective temperature control solutions has never been greater. Among the various cooling systems available, OEM small industrial chillers have emerged as a popular choice for businesses aiming to maintain optimal operational conditions while minimizing energy consumption. This article delves into what OEM small industrial chillers are, their advantages, and their applications across various industries.

What is an OEM Small Industrial Chiller?

OEM, or Original Equipment Manufacturer, refers to companies that design and build products that are later marketed under another company's brand. Small industrial chillers manufactured by OEMs are compact cooling systems designed for various industrial applications. These chillers are engineered to provide reliable cooling solutions, capable of efficiently managing the heat load generated by industrial processes, machinery, and other equipment.

Advantages of OEM Small Industrial Chillers

1. Customized Solutions One of the standout features of OEM small industrial chillers is their customization options. Manufacturers can tailor these chillers to meet specific operational requirements, ensuring they are optimally configured for unique applications. This customization extends to various parameters, including size, capacity, and cooling method, allowing businesses to implement solutions that perfectly fit their needs.

2. Energy Efficiency Modern OEM chillers are designed with energy efficiency in mind. With advancements in technology, these systems often include energy-saving features such as variable speed drives, high-efficiency compressors, and heat recovery options. By reducing energy consumption, businesses not only lower their operational costs but also contribute to sustainability efforts.

oem small industrial chiller

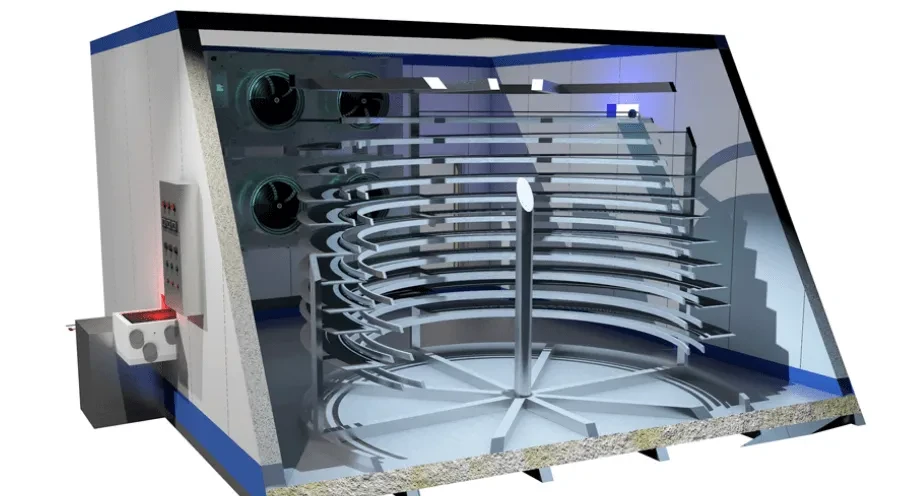

3. Compact Design Small industrial chillers are designed to fit into tight spaces, making them ideal for facilities where floor space is limited. Their compact design does not compromise efficiency, allowing manufacturers to install these chillers in various industrial environments without extensive renovations.

4. Reliability and Durability OEM chillers are built to withstand the rigors of industrial applications. Constructed from high-quality materials and components, these chillers offer enhanced durability and long life. Regular maintenance, paired with robust manufacturing processes, ensures that these systems operate reliably over time.

5. Versatile Applications OEM small industrial chillers are used across a wide spectrum of industries, including plastics manufacturing, food and beverage processing, pharmaceutical production, and HVAC applications. Their versatility makes them suitable for applications such as cooling injection molding machines, maintaining precise temperature control in fermentation processes, or managing heat loads in data centers.

6. Technical Support and Service OEM manufacturers typically offer excellent customer support and service. This includes not only installation assistance but also ongoing maintenance and troubleshooting. Having access to informed technicians enhances operational efficiency and minimizes downtime.

Conclusion

In conclusion, OEM small industrial chillers represent a pivotal investment for businesses seeking efficient and customizable cooling solutions. With their tailored options, energy efficiency, reliability, compact design, and versatility, these chillers are integral to maintaining optimal performance in various industrial applications. As industries evolve and the push for sustainable practices continues, the role of OEM small industrial chillers will be increasingly significant in creating more efficient and environmentally-friendly operational environments. By choosing the right OEM chiller, companies can improve their productivity while keeping energy costs in check, ultimately resulting in a more sustainable and profitable operation.