Tube Ice Machine Maker Leading Manufacturer for Efficient Ice Production Solutions

The Rise of Tube Ice Machine Manufacturers Meeting Global Demand for Ice Production

In recent years, the demand for ice, particularly tube ice, has surged across various sectors, including food and beverage, hospitality, and seafood industries. This increased demand has paved the way for innovations in ice-making technology and has seen a significant rise in the number of tube ice machine manufacturers globally.

Tube ice is favored for its hollow shape, which allows for better cooling efficiency and rapid chilling. It is commonly employed in the transportation and storage of perishable goods, particularly seafood, as it minimizes damage during transit. The versatility of tube ice makes it an essential product in industries that prioritize freshness and quality.

The Technology Behind Tube Ice Machines

Modern tube ice machines are engineered to produce high-quality ice in large quantities. These machines utilize advanced refrigeration technology that operates on a closed-loop system. The process typically involves the use of refrigerants to cool water, which subsequently freezes on the surfaces of specially designed molds. Once the ice forms, it is automatically harvested and typically stored in a silo or production bin, ready for distribution.

Manufacturers are continually innovating their designs to improve efficiency and reduce energy consumption. For example, some machines are equipped with sensors and smart controls that optimize production cycles based on demand. This not only enhances energy efficiency but also ensures that businesses can access ice when they need it without the excess cost of continuous production.

Choosing the Right Tube Ice Machine Manufacturer

tube ice machine maker manufacturer

When selecting a tube ice machine manufacturer, several critical factors come into play. Firstly, the production capacity is a primary consideration—businesses must determine their daily ice requirements to choose a machine that can meet their needs without incurring unnecessary costs. Manufacturers often offer a range of machines, from smaller units suitable for restaurants and bars to large-scale commercial setups for fish markets and distribution centers.

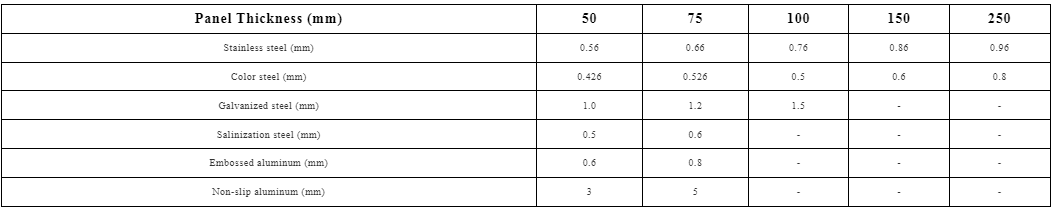

Quality and reliability are non-negotiable elements in this industry. Reputable manufacturers provide warranties and after-sales support, ensuring that their machines operate efficiently over time. Potential buyers should also pay attention to the materials used in construction, as durable, corrosion-resistant materials extend the lifespan of ice machines.

Additionally, energy efficiency has become a crucial selling point. In an era of rising energy costs and growing environmental awareness, businesses are increasingly seeking machines that minimize energy consumption. Many manufacturers are investing in eco-friendly technologies that reduce their carbon footprint while still delivering high outputs.

The Future of Tube Ice Production

Looking ahead, the global market for tube ice machines is poised for continued growth. The surge in the seafood industry, along with developments in food logistics and hospitality, will drive demand for reliable and efficient ice production systems. Manufacturers will likely respond with more sophisticated machines—perhaps incorporating features like IoT connectivity for real-time monitoring and maintenance alerts.

Moreover, as sustainability becomes a key focus across industries, tube ice machine manufacturers will need to prioritize eco-friendly practices in their processes. This could include the adoption of natural refrigerants and design improvements aimed at reducing water consumption.

In conclusion, the rise of tube ice machine manufacturers reflects the growing need for efficient, reliable ice production across multiple industries. By leveraging technological advancements and prioritizing sustainability, these manufacturers are well-positioned to support the global demand for ice, ensuring that industries reliant on this vital resource can continue to thrive. As businesses strive for efficiency and quality, the role of the tube ice machine manufacturer will remain integral to the ice supply chain of the future.