Comprehensive Guide to High-Performance Industrial Frigo Chiller Systems

High Quality Industrial Frigo Chiller Manual

Frigo chillers are essential components in many industrial applications, providing efficient cooling solutions for various processes. Understanding the operation, maintenance, and safety procedures of high-quality industrial frigo chillers is crucial for ensuring optimal performance and longevity. This manual aims to guide users through the essential aspects of these sophisticated cooling systems.

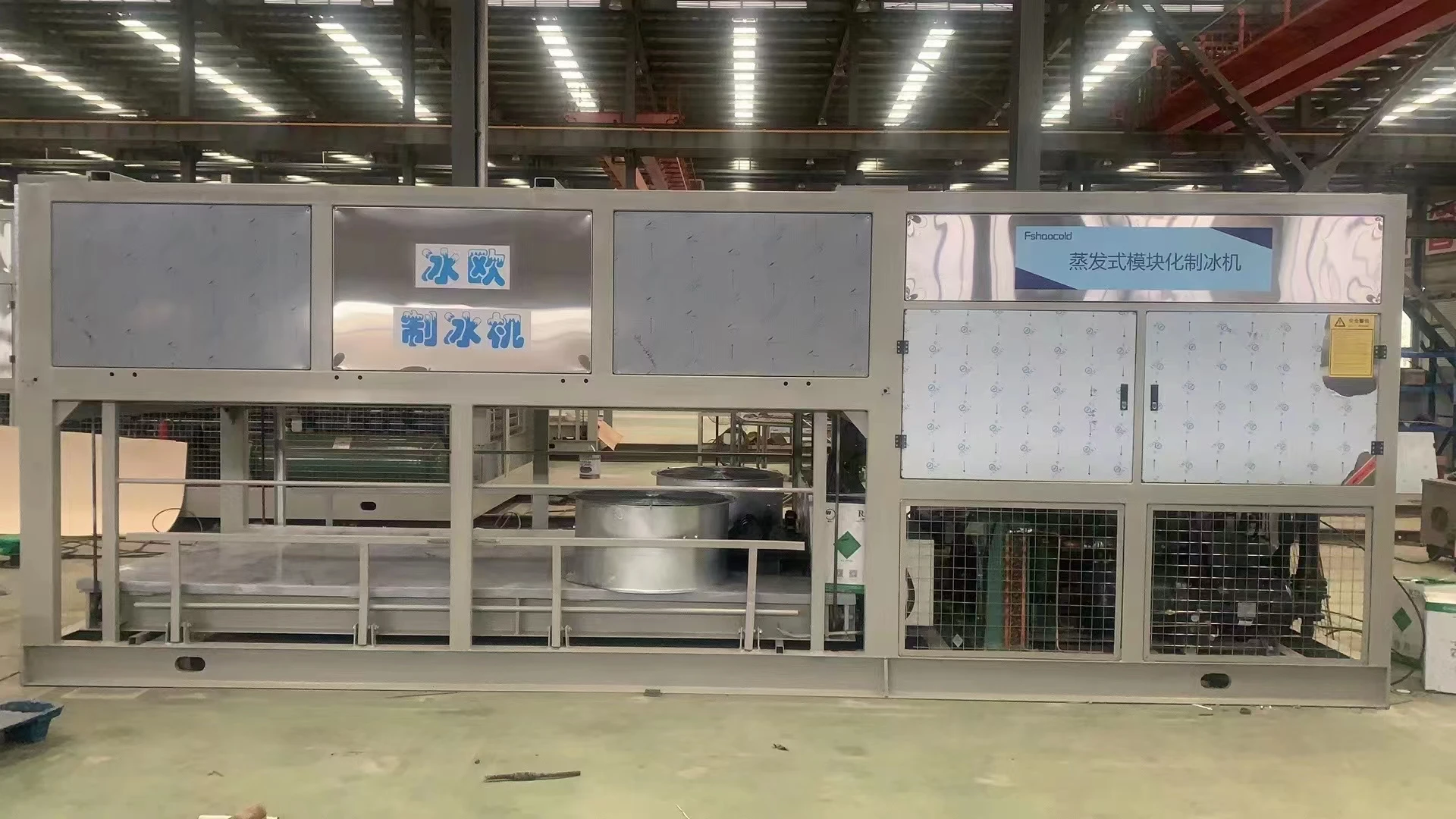

Overview of Frigo Chillers

Frigo chillers work by removing heat from a liquid through a vapor-compression or absorption refrigeration cycle. The primary components include a compressor, condenser, expansion valve, and evaporator. Understanding how each part functions will help users identify and troubleshoot potential issues. It's imperative to choose high-quality frigo chillers designed for durability and efficient performance to meet the demands of industrial environments.

Installation Guidelines

Proper installation is critical for ensuring the efficient operation of frigo chillers. When installing a chiller, consider the following guidelines

1. Site Selection Choose a location with adequate space for airflow around the chiller. Avoid areas with direct sunlight or excessive dust that could impair performance.

2. Level Foundation Ensure the unit is placed on a level foundation to prevent undue stress on the components, which could lead to premature wear or failure.

3. Piping Connections Use insulated piping for both chilled water and refrigerant lines to minimize heat gain and loss. Proper sizing of pipes will also enhance efficiency.

4. Electrical Setup Ensure that the electrical connections meet the manufacturer’s specifications, and consider employing a professional electrician for complex setups.

5. Safety Precautions Install safety devices such as pressure relief valves and thermal protection to safeguard the chiller from operational hazards.

Operating Instructions

Once installed, familiarize yourself with the chiller’s control panel. Most high-quality frigo chillers come equipped with advanced control systems allowing for precise temperature management. Set operational parameters according to the specific cooling needs of your processes while adhering to manufacturer recommendations.

Monitor vital performance indicators such as

high quality industrial frigo chiller manual

- Water Inlet and Outlet Temperature Ensure that the differential temperature meets process requirements. - Refrigerant Pressure Regularly check the refrigerant pressure gauges to confirm they are within the prescribed operating range.

Regular monitoring not only optimizes performance but also helps in early detection of potential issues.

Maintenance Procedures

Regular maintenance is essential for the longevity of frigo chillers. Here are some key maintenance practices

1. Clean Condenser Coils Dust and debris can build up on the coils, reducing efficiency. Periodically clean the coils to ensure optimal heat exchange.

2. Check Refrigerant Levels Monitor and maintain proper refrigerant levels. Low levels can indicate leaks that must be addressed immediately.

3. Inspect Electrical Components Look for signs of wear in wiring and connections. Ensure all components are securely connected to prevent electrical failures.

4. Lubricate Moving Parts Regularly lubricate compressor bearings and other moving parts to minimize friction and wear.

5. Conduct Routine Inspections Schedule routine inspections with qualified technicians to identify and rectify potential issues before they escalate into costly repairs.

Safety Measures

Safety is a top priority when operating industrial frigo chillers. Always wear appropriate personal protective equipment (PPE) when handling refrigerants or performing maintenance tasks. Familiarize yourself with the manufacturer's safety instructions and ensure that all personnel involved in operations are adequately trained.

Additionally, establish emergency procedures for handling refrigerant leaks or equipment failures to protect personnel and the facility.

Conclusion

A high-quality industrial frigo chiller is a valuable investment for any facility requiring effective cooling solutions. By adhering to the guidelines outlined in this manual, operators can ensure efficient operation, prolong the lifespan of the equipment, and maintain a safe working environment. Regular attention to installation, operation, maintenance, and safety procedures will maximize the benefits of your frigo chiller, supporting the overall success of your industrial processes.