box type condensing unit factories

Box Type Condensing Unit Factories An Overview

In today’s rapidly evolving industrial landscape, box type condensing units have garnered significant attention due to their efficiency and versatility. As the need for effective cooling systems grows across various sectors—including refrigeration, HVAC (heating, ventilation, and air conditioning), and industrial processing—box type condensing unit factories are playing a crucial role in meeting this demand. These factories are responsible for designing, manufacturing, and supplying these units, which are essential for various applications, from food preservation to temperature regulation in commercial buildings.

Understanding Box Type Condensing Units

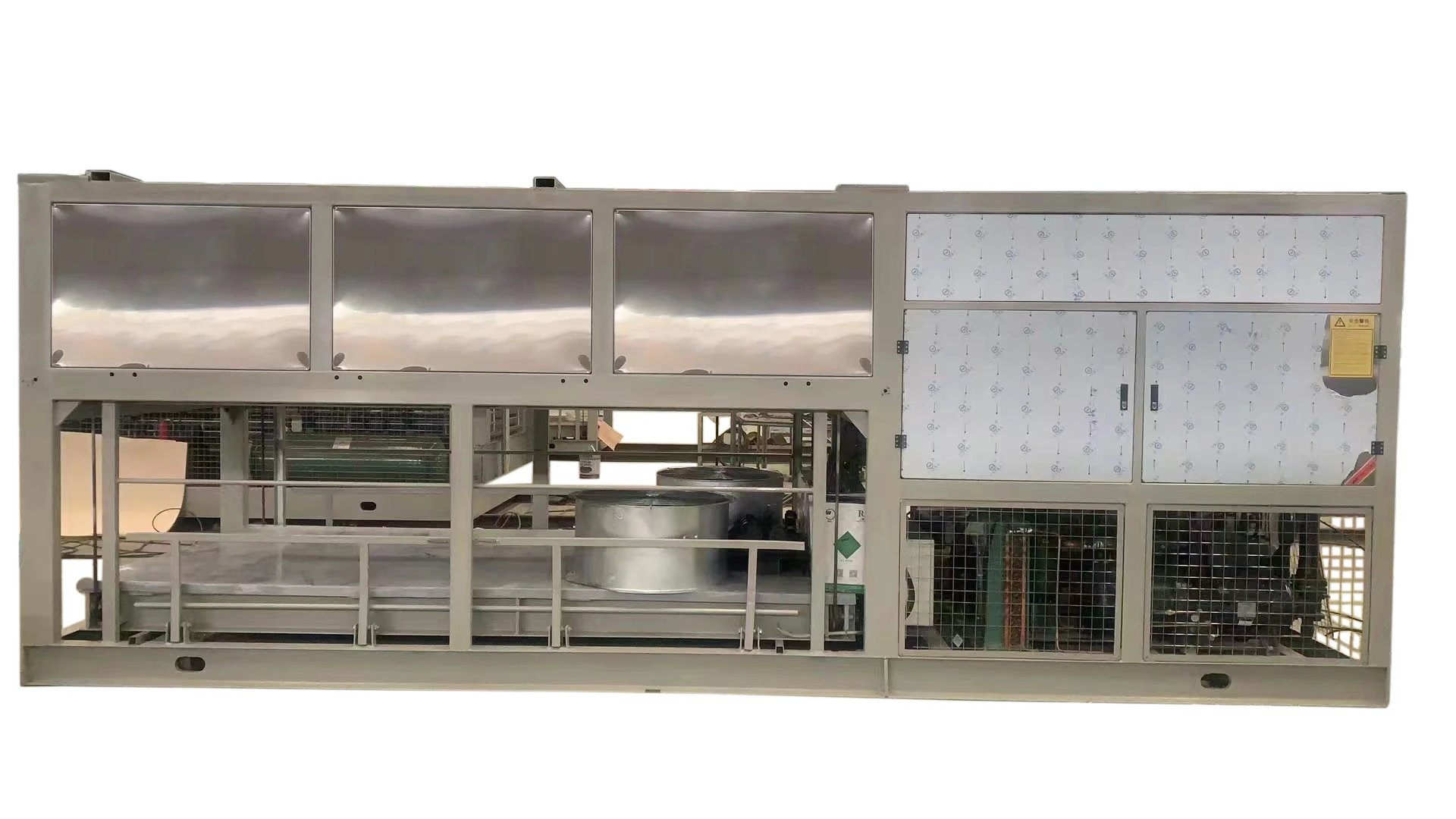

Box type condensing units are compact refrigeration systems that integrate a condenser, compressor, evaporator, and expansion valve, often packaged into a single insulated box. This design not only conserves space but also enhances the system's efficiency by minimizing heat loss. These units are typically used in commercial refrigeration setups, such as in supermarkets, restaurants, and cold storage facilities.

One of the key advantages of box type condensing units is their ability to operate effectively in diverse environments, from warm climates to cold storage applications. They are designed to be energy efficient, often utilizing advanced technological components to optimize performance and reduce energy consumption. This efficiency translates to lower operational costs and a smaller carbon footprint, which is increasingly important in today’s eco-conscious market.

The Role of Factories

The factories that produce box type condensing units are not merely manufacturing facilities; they are hubs of innovation and technology. These factories employ skilled engineers and technicians to design systems that meet varying customer requirements. The production process involves several stages, including research and development, prototyping, assembly, and rigorous testing. This meticulous approach ensures that the final products are not only reliable but also compliant with industry standards and regulations.

Quality control is a significant aspect of the manufacturing process. Factories employ various testing methodologies to ensure that each unit operates under different conditions effectively. These tests often include performance evaluations under extreme temperatures and humidity levels, ensuring that the units can perform as expected when deployed in real-world situations.

box type condensing unit factories

Innovation in Manufacturing

As the market for box type condensing units continues to expand, factories are embracing new technologies to enhance production efficiency and product quality. Automation has become increasingly prevalent, with robotics and advanced machinery streamlining the assembly line. This not only improves production speed but also reduces the margin for error, resulting in higher-quality products.

Additionally, factories are investing in research and development to incorporate sustainable materials and technologies into their products. For example, there is a growing trend towards using refrigerants with lower global warming potentials and incorporating energy recovery systems to improve efficiency. This shift aligns with global efforts to combat climate change and meet sustainability targets.

Global Market and Opportunities

The demand for box type condensing units is experiencing significant growth globally, driven by the expansion of the food and beverage sector, pharmaceutical industries, and the rising need for effective climate control systems in commercial buildings. This growing market presents opportunities for manufacturers to expand their operations and reach new customers.

Emerging markets, in particular, are becoming critical spaces for growth in the box type condensing unit sector. As developing countries continue to urbanize and industrialize, the demand for efficient cooling solutions is expected to soar. Factories that can adapt quickly to the needs of these markets, offering customizable solutions and competitive pricing, will likely find success.

Conclusion

Box type condensing unit factories are at the forefront of innovation in the cooling industry, combining technology and engineering excellence to produce efficient and reliable systems. With the increasing demand for sustainable and energy-efficient refrigeration solutions, these factories are not just manufacturers—they are vital contributors to the global economy and environmental efforts. As they continue to evolve, they will play an instrumental role in shaping the future of climate control and refrigeration technology. The journey ahead is filled with potential, as these factories drive advancements that meet both industrial needs and environmental imperatives.

-

Transform Operations with Vacuum Freezer MachineNewsMay.14,2025

-

Enhance Business with Cold Room TechnologyNewsMay.14,2025

-

Vacuum Freezer Machine for Modern NeedsNewsMay.09,2025

-

Discover Our Comprehensive Cold Room SolutionsNewsMay.09,2025

-

Cold Room Solutions for Your BusinessNewsMay.08,2025

-

Advanced Vacuum Freezer MachineNewsMay.08,2025