industrial water chiller price manufacturer

Understanding Industrial Water Chiller Prices and Manufacturers

The demand for industrial water chillers has surged in recent years as businesses look for efficient ways to manage their cooling needs. Whether in manufacturing processes, food production, or any sector requiring temperature control, water chillers provide a reliable solution. In this article, we will explore the factors influencing industrial water chiller prices, the role of manufacturers, and tips for selecting the right unit for your requirements.

What is an Industrial Water Chiller?

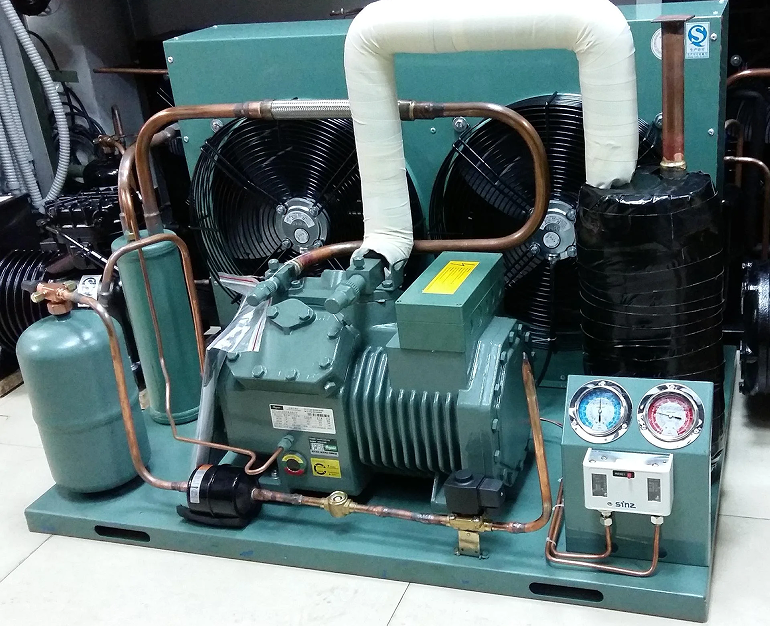

Industrial water chillers are systems designed to remove heat from a liquid through a vapor-compression or absorption refrigeration cycle. The chilled liquid is then circulated within the building to cool machines, processes, or large facilities. They are crucial in industries such as chemicals, pharmaceuticals, plastics, and food and beverage, where precise temperature control is essential for maintaining product quality and equipment efficiency.

Factors Affecting Prices

1. Type of Chiller The price of an industrial water chiller can vary significantly based on its type. Air-cooled chillers generally have a lower upfront cost compared to water-cooled chillers. However, water-cooled chillers can be more efficient in the long term, especially in larger applications, thus leading to savings in operational costs.

2. Cooling Capacity Chillers come in various sizes, typically measured in tonnage, which indicates their cooling capacity. Larger chillers that can handle increased workloads will naturally come at a higher price point due to the advanced technology and materials involved in their construction.

3. Energy Efficiency Ratings Many manufacturers offer chillers with different energy efficiency levels, often indicated by the coefficient of performance (COP) or the energy efficiency ratio (EER). Higher efficiency models might cost more initially but can result in substantial savings on energy bills over time.

4. Cooling Medium The type of refrigerant used in the chiller can also influence its price. Environmentally friendly refrigerants may be more expensive but are increasingly necessary due to stringent regulations surrounding greenhouse gas emissions.

5. Manufacturer Reputation Established manufacturers with a track record of reliability and performance will often command higher prices. However, investing in reputable brands often translates to enhanced durability and better customer support, which can be worth the extra cost.

industrial water chiller price manufacturer

6. Customization and Features Industrial chillers can be customized with various features such as digital controls, remote monitoring, and integration with existing HVAC systems. These added functionalities can increase the initial investment but can also enhance overall efficiency and control.

Selecting the Right Manufacturer

When looking for an industrial water chiller, it's crucial to evaluate potential manufacturers carefully. Key considerations include

- Experience and Expertise Look for manufacturers with extensive experience in producing chillers for your specific industry. Their understanding of industry standards and requirements is invaluable.

- Warranty and Support A strong warranty and responsive customer service are essential. A good manufacturer should provide comprehensive support for installation and maintenance, ensuring your chiller operates smoothly over its lifespan.

- Reviews and Testimonials Investigate customer reviews and testimonials to gauge the performance and reliability of the manufacturer's chillers. Feedback from other businesses in your industry can provide insight into the chiller's effectiveness and longevity.

- Energy Efficiency Innovations Manufacturers that prioritize research and development tend to produce more advanced, energy-efficient products. In today’s market, opting for efficient systems not only saves money but also reduces the carbon footprint of your operations.

Conclusion

Investing in an industrial water chiller is a significant decision that can impact operational efficiency and costs. Understanding the various factors that affect pricing, alongside choosing the right manufacturer, is crucial to making an informed choice. By focusing on your specific cooling needs and balancing initial costs with long-term savings, you can select a high-quality water chiller that meets the demands of your industry. Remember, the right water chiller not only contributes to operational efficiency but also enhances product quality and extends the life of your machinery.