Cold Room Panels For Sale | Insulated & Durable Solutions

The Imperative of High-Performance Cold Room Panels in Modern Logistics & Storage

In today's global economy, the integrity of cold chain logistics is paramount for industries ranging from food and pharmaceuticals to chemicals and floriculture. At the heart of any efficient cold storage facility are superior insulation solutions. When businesses look for cold room panels for sale, they are investing in more than just building materials; they are securing the foundation for energy efficiency, product quality, and operational reliability. These specialized panels are engineered to maintain precise temperature conditions, minimize thermal bridging, and withstand harsh environmental stresses, directly impacting operational costs and product shelf life.

The demand for robust cold storage infrastructure continues to surge, driven by increasing consumer expectations for fresh produce, the complex needs of the pharmaceutical supply chain, and the expansion of e-commerce requiring extensive temperature-controlled warehousing. This section delves into the critical role of these panels, exploring market trends, essential technical specifications, and the tangible benefits they offer across diverse industrial applications. Understanding these nuances is crucial for any business aiming to optimize its cold chain and ensure long-term sustainability.

Decoding Cold Room Panel Technology: Materials and Performance Metrics

The performance of cold room panels for sale is fundamentally determined by their core insulating material and external cladding. The most common core materials are Polyurethane (PUR) and Polyisocyanurate (PIR) foam, renowned for their exceptional thermal insulation properties. PIR, in particular, offers enhanced fire resistance compared to standard PUR, a critical consideration for safety and compliance. The panel's outer skins are typically made of pre-painted galvanized iron (PPGI), stainless steel (SS), or aluminum, selected based on the specific environmental conditions and hygiene requirements of the cold room. For instance, stainless steel is preferred in highly corrosive or hygienic environments like food processing plants due to its superior resistance to chemicals and ease of cleaning.

Key performance metrics for insulated cold storage panels include thermal conductivity (lambda value, λ), which measures how easily heat passes through a material; R-value, representing thermal resistance; and U-value, indicating the overall heat transfer coefficient of the entire panel assembly. Lower lambda values and U-values, coupled with higher R-values, signify superior insulation capabilities, leading to reduced energy consumption and more stable internal temperatures. Panels are often connected using a cam-lock system, ensuring a tight, thermally sealed joint that prevents thermal bridges, crucial for maintaining optimal cold room performance.

Typical Cold Room Panel Specifications

| Parameter | Description | Typical Value Range |

|---|---|---|

| Core Material | Polyurethane (PUR) or Polyisocyanurate (PIR) foam | PUR (Density: 40-42 kg/m³), PIR (Density: 42-45 kg/m³) |

| Thermal Conductivity (λ) | Heat transfer capability of the material | 0.020 - 0.024 W/(m·K) |

| Panel Thickness | Overall thickness, impacting R-value | 75mm, 100mm, 120mm, 150mm, 200mm |

| R-Value (Thermal Resistance) | Resistance to heat flow per unit area | R-28 to R-50 (for 100mm to 200mm panels) |

| Facing Material | Outer skin material | PPGI (0.5mm), Stainless Steel (0.6mm), Aluminum (0.7mm) |

| Fire Rating | Resistance to fire spread (for PIR) | B2 (PUR), B1 (PIR), or FM Approved equivalent |

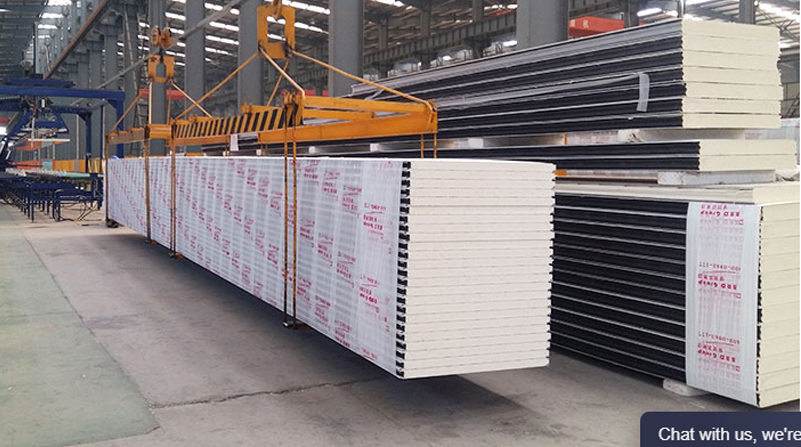

The Manufacturing Precision of Cold Room Panels

The production of high-quality cold storage panels for sale involves a sophisticated, often automated, manufacturing process designed to ensure consistent insulation performance and structural integrity. The core principle involves injecting a liquid polyurethane or polyisocyanurate mixture between two metal sheets, which then expands and cures, forming a dense, closed-cell foam that adheres firmly to the facings. This process, known as continuous lamination or discontinuous foaming, is critical for achieving uniform density and preventing voids that could compromise insulation.

The manufacturing workflow typically includes several key stages:

- Material Preparation: High-grade steel or aluminum coils are uncoiled, cleaned, and pre-treated to ensure optimal adhesion with the foam core. This often involves chemical washing and priming.

- Profiling & Forming: The metal sheets are then profiled into specific shapes (e.g., tongue-and-groove or cam-lock edges) to ensure precise interlocking during installation and minimize thermal bridging.

- Foam Injection/Lamination: In continuous lines, the liquid foam components are mixed and dispensed onto the lower skin, covered by the upper skin, and passed through a heated press that controls thickness and initiates curing. For discontinuous processes, pre-cut sheets are placed in a mold, and foam is injected under high pressure.

- Curing & Cutting: The panels undergo a curing period, either in a continuous oven or a static press, to achieve full structural integrity. They are then cut to precise lengths based on client specifications.

- Quality Control & Testing: Each batch undergoes rigorous testing to ensure compliance with standards like ISO 9001 for quality management. Tests include foam density checks, adhesion strength between core and skin, thermal conductivity measurements (e.g., using a heat flow meter apparatus), and dimensional accuracy. Fire resistance tests (e.g., ASTM E84, EN 13501) are also performed, especially for PIR panels.

Strategic Advantages and Diverse Applications of Cold Room Panels

Investing in high-quality cold room panels for sale offers a multitude of strategic advantages for businesses operating in temperature-sensitive sectors. Foremost among these is unparalleled energy efficiency. The advanced insulation properties of PUR and PIR panels drastically reduce the energy required to maintain low temperatures, leading to significant reductions in operational costs and a lower carbon footprint. Furthermore, their modular design facilitates rapid installation, minimizing downtime during construction or expansion projects. The panels are also highly durable, resistant to moisture, mildew, and corrosion (especially those with stainless steel facings), ensuring a hygienic environment crucial for food and pharmaceutical safety. Their robust construction contributes to an extended service life, minimizing the need for frequent replacements.

The versatility of insulated cold storage panels makes them indispensable across a wide array of industries:

- Food & Beverage: From large-scale food processing plants and distribution centers to restaurants and supermarkets, cold room panels are vital for preserving perishable goods, ensuring food safety, and extending shelf life.

- Pharmaceuticals & Healthcare: Strict temperature control is non-negotiable for medicines, vaccines, and sensitive biological samples. Panels provide the stable, sterile environments required for compliance with GxP (Good Practice) regulations.

- Logistics & Warehousing: Cold storage warehouses facilitate the global distribution of temperature-sensitive products, optimizing supply chains and reducing spoilage.

- Agriculture & Floriculture: Farmers and florists rely on cold rooms to extend the freshness of produce, flowers, and seeds, improving marketability and reducing waste.

- Specialized Industrial Applications: Certain chemical storage, testing laboratories, and precision manufacturing processes require stable low temperatures, making cold room panels an ideal solution for controlled environments.

Selecting a Cold Room Panel Manufacturer: A Strategic Decision

Choosing the right partner among cold room panel manufacturers is paramount to the success and longevity of your cold storage project. A reputable manufacturer doesn't just supply panels; they offer comprehensive solutions, from design consultation to post-installation support. Key factors to consider include the manufacturer's experience in diverse applications, their adherence to international quality standards (such as ISO 9001 and specific fire safety certifications like FM Approvals or CE marking), and their ability to provide customized solutions. Companies that invest in R&D to improve insulation performance, fire resistance, and environmental sustainability often stand out.

Customization is a significant advantage offered by leading manufacturers. Whether you require specific panel dimensions, varying insulation thicknesses like 100mm cold room panels for chiller rooms versus 150mm or 200mm for freezers, or specialized surface finishes (e.g., anti-bacterial coatings, heavy-duty stainless steel for washdown areas), a flexible manufacturer can tailor products to precise project requirements. This includes custom door solutions (swing, sliding, or vertical lift doors), flooring options, and integrated accessories like viewing windows or pressure equalization ports. Our commitment to delivering bespoke cold storage solutions ensures optimal performance and seamless integration with your existing infrastructure, reflecting over a decade of industry expertise and client-centric service.

Manufacturer Comparison Checklist

| Criteria | Reputable Manufacturer | Standard Manufacturer |

|---|---|---|

| Certifications | ISO 9001, CE, FM Approved, Local Fire Ratings | Basic ISO or none |

| Product Range | Wide range of thicknesses (75-200mm), core materials (PUR/PIR), facing options (PPGI, SS, Aluminum) | Limited thicknesses, often only PUR, standard PPGI |

| Customization | Full customization for dimensions, doors, accessories | Minimal or no customization |

| Technical Support | Design, engineering, installation guidance, after-sales service | Basic product information only |

| Warranty & Service Life | Comprehensive warranty (5-10 years), >20 years service life | Limited warranty (1-2 years), shorter expected life |

Realizing Value: Case Studies and Client Success with Cold Room Panels

The practical impact of deploying high-quality cold room panels for sale is best illustrated through real-world applications and client success stories. These panels are not merely components; they are integral to creating robust, energy-efficient, and compliant cold storage environments that directly contribute to business profitability and operational excellence. From large distribution hubs requiring expansive freezer storage to smaller, specialized temperature-controlled chambers for sensitive materials, the right panel selection translates into tangible benefits.

Consider a pharmaceutical client who needed to establish a new 500 cubic meter cold room for vaccine storage at -20°C. By utilizing insulated cold storage panels with a 150mm PIR core and pharmaceutical-grade stainless steel facings, the client achieved:

- Energy Savings: Post-installation monitoring showed energy consumption 25% lower than initially projected, thanks to the panels' superior thermal performance and minimized thermal bridging.

- Regulatory Compliance: The chosen panels, compliant with FDA and ISO standards, facilitated swift regulatory approval, ensuring the facility met stringent GxP guidelines.

- Rapid Deployment: The modular nature of the panels allowed for completion of the cold room structure in under two weeks, significantly reducing project timelines and accelerating operational readiness.

Trust and Reliability: Your Partner for Cold Room Solutions

At the core of our commitment to clients looking for cold room panels for sale is building enduring trust through transparency, reliable products, and comprehensive support. We understand that investing in cold storage infrastructure is a significant decision, and our aim is to simplify this process while ensuring the highest standards of quality and service. Our manufacturing processes adhere strictly to ISO 9001 quality management systems, guaranteeing consistent product excellence. Each panel undergoes rigorous internal testing, including dimensional checks, foam density analysis, and thermal performance verification, to ensure it meets both our stringent benchmarks and international industry standards.

Frequently Asked Questions (FAQ)

- Q: What is the typical delivery timeframe for cold storage panels for sale?

A: Standard orders typically have a lead time of 15-25 business days from order confirmation, depending on customization and order volume. Expedited options are available upon request. - Q: What warranty is provided with your insulated cold storage panels?

A: We offer a comprehensive 5-year warranty on all panels against manufacturing defects, underscoring our confidence in product durability and performance. Extended warranty options can be discussed. - Q: Can you provide installation guidance for 100mm cold room panels?

A: Yes, we provide detailed installation manuals, technical drawings, and online support. For larger or more complex projects, we can arrange for on-site technical supervision or recommend certified installation partners. - Q: How do your panels contribute to energy efficiency?

A: Our panels utilize high-density PUR/PIR foam with low thermal conductivity, and their precise interlocking (cam-lock) design minimizes thermal bridging, significantly reducing heat gain and thus, refrigeration energy consumption.

Our dedicated customer support team is available to assist you from initial inquiry and project planning through to after-sales service. We believe in fostering long-term partnerships, ensuring that your investment in our `cold room panels for sale` yields maximum return and operational peace of mind.

Conclusion: The Future of Cold Storage Demands Superior Panels

The increasing complexity of global supply chains and the stringent requirements for temperature-controlled environments underscore the indispensable role of high-quality cold room panels for sale. As industries continue to expand and diversify, the demand for energy-efficient, durable, and hygienically compliant cold storage solutions will only intensify. Choosing advanced insulated cold storage panels is not merely a purchase; it's a strategic investment in operational efficiency, product integrity, and long-term sustainability.

By understanding the technical nuances, manufacturing precision, and diverse applications of these essential building blocks, businesses can make informed decisions that safeguard their valuable products and optimize their cold chain operations. Partnering with experienced cold room panel manufacturers who prioritize quality, customization, and comprehensive support ensures that your cold storage facility is built for peak performance and prepared for future demands. Embrace the future of cold storage with panels engineered for excellence, ensuring your products remain safe, fresh, and compliant every step of the way.

References

- International Organization for Standardization (ISO). (2015). ISO 9001:2015 Quality management systems – Requirements.

- ASTM International. (2017). ASTM E84-17: Standard Test Method for Surface Burning Characteristics of Building Materials.

- European Committee for Standardization (CEN). (2018). EN 13501-1: Fire classification of construction products and building elements – Part 1: Classification using data from reaction to fire tests.

- ASHRAE. (2021). ASHRAE Handbook - Fundamentals. American Society of Heating, Refrigerating and Air-Conditioning Engineers.

- Food and Drug Administration (FDA). (2020). Good Manufacturing Practice (GMP) Guidelines for Food and Drug Products.