ice block making machine factory

The Rise of Ice Block Making Machine Factories

In recent years, the demand for ice has surged across various industries, including food and beverage, hospitality, and healthcare. This rising demand has led to the development of specialized factories dedicated to the production of ice block making machines. These factories not only cater to large-scale ice production but also ensure that communities have access to safe and high-quality ice for their needs.

The Importance of Ice in Various Industries

Ice blocks are crucial in numerous sectors. In the food industry, they are used for preserving perishable items during transport and storage. Restaurants and catering businesses rely on ice to keep drinks cold and food items fresh. In the healthcare sector, ice is essential for storing biological samples and as a coolant for patients with injuries or illnesses. The hospitality industry also utilizes ice for providing comfortable experiences in bars, hotels, and event centers. With such diverse applications, the need for efficient ice block making machines has never been greater.

Evolution of Ice Block Making Machines

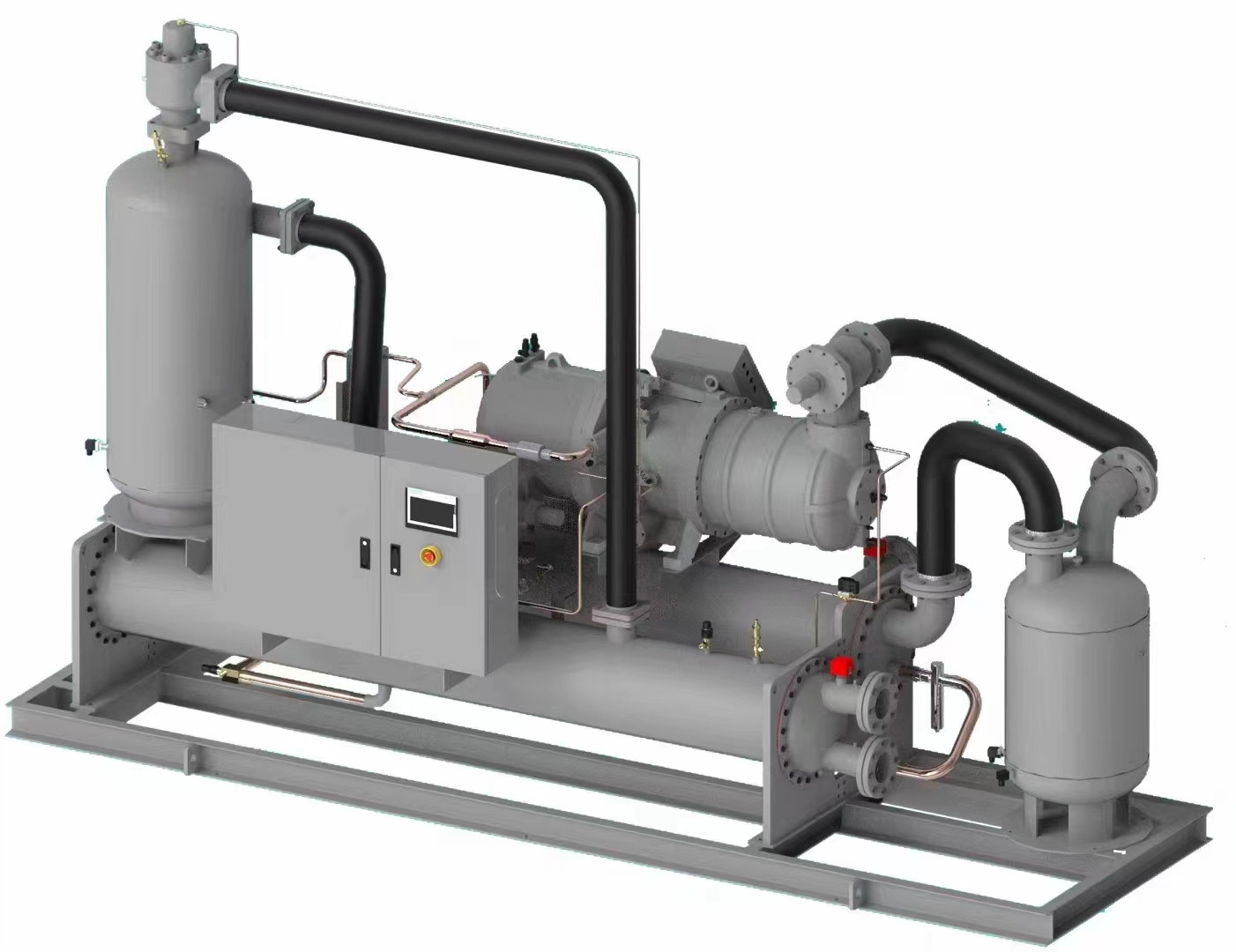

The evolution of ice block making machines has been remarkable over the years. Initially, ice production was a labor-intensive process that relied heavily on natural freezing methods. However, advancements in technology have transformed this landscape. Modern ice block making machines are designed to produce large volumes of ice efficiently and quickly. These machines incorporate innovative refrigeration technologies that minimize energy consumption while maximizing output. Additionally, improvements in materials and design have enhanced the durability and reliability of these machines, making them ideal for high-demand environments.

Key Features of Ice Block Making Machines

ice block making machine factory

Ice block making machines come with a variety of features that cater to the needs of different industries. Some machines can produce ice blocks of varying sizes, allowing users to customize their ice production according to specific requirements. Many modern machines are equipped with automated controls, enabling operators to monitor the ice-making process remotely, ensuring optimal production efficiency. Hygiene is another important consideration; therefore, many machines are built with food-grade materials that comply with health regulations. This ensures that the ice produced is safe for consumption and storage.

The Process of Ice Block Production

The production process of ice blocks in factories involves several steps. First, water is purified to eliminate impurities that could affect the quality of the ice. This purified water is then introduced into the ice making machine, where it is rapidly cooled. As the water freezes, it forms solid blocks of ice that can weigh anywhere from 5 to 50 kg or more, depending on the machine’s specifications. Once the freezing process is complete, the ice is harvested and packaged for distribution. Some factories even incorporate storage facilities where the ice blocks can be stored before distribution, ensuring a continuous supply chain.

Environmental Considerations

With the increasing focus on environmental sustainability, many ice block making machine factories are adopting eco-friendly practices. This includes the use of environmentally-friendly refrigerants that have a lower impact on the ozone layer and energy-efficient systems that reduce overall energy consumption. Furthermore, some factories are implementing water recycling systems to minimize waste and conserve resources.

Conclusion

The establishment of ice block making machine factories is a significant development in meeting the growing demand for ice across various industries. With continuous technological advancements and a commitment to sustainability, these factories play a crucial role in ensuring the efficient production of high-quality ice. As industries evolve and the demand for ice persists, the future looks bright for ice block making machine production, offering a vital service to communities and businesses alike.