Companies Specializing in Ice Machine Drainage and Air Gap Solutions

Understanding Ice Machine Drain Air Gap Importance and Best Practices

In commercial kitchens and food service establishments, ice machines play a crucial role in ensuring that beverages are served cold and that food items are stored at safe temperatures. However, the efficient operation of ice machines requires not only proper maintenance but also adherence to critical plumbing standards, particularly regarding the drain systems. One essential concept that facility managers and kitchen operators should understand is the air gap associated with ice machine drains.

What is an Air Gap?

An air gap is a physical separation between the outlet of a drainage pipe and the water level in a receptacle, such as a sink or drain. In the context of ice machines, the air gap is designed to prevent backflow, a condition where used or contaminated water could flow back into the ice machine's water supply. Without an adequate air gap, there is a risk of cross-contamination, which can compromise the quality of the ice produced and pose health risks.

The Importance of Air Gaps in Ice Machines

1. Health and Safety Compliance Health departments mandate specific guidelines to ensure the sanitary operation of food facilities. Implementing an air gap in the drain line of ice machines is often required to comply with local and national regulations, including the Food and Drug Administration (FDA) Food Code. Non-compliance can lead to fines, loss of operating licenses, or, in severe cases, temporary closure of the establishment.

2. Protection from Contaminants Ice produced by machines is often used in drinks and food service. A well-implemented air gap protects the ice from potential contaminants that could flow back from the drain. This includes substances from cleaning agents or waste materials, which could be present in drainage systems.

3. Improved Equipment Longevity Maintaining a proper drainage system with an air gap can enhance the longevity and efficiency of ice machines. Reducing the likelihood of contaminants entering the system means fewer repairs and a longer lifespan for the equipment.

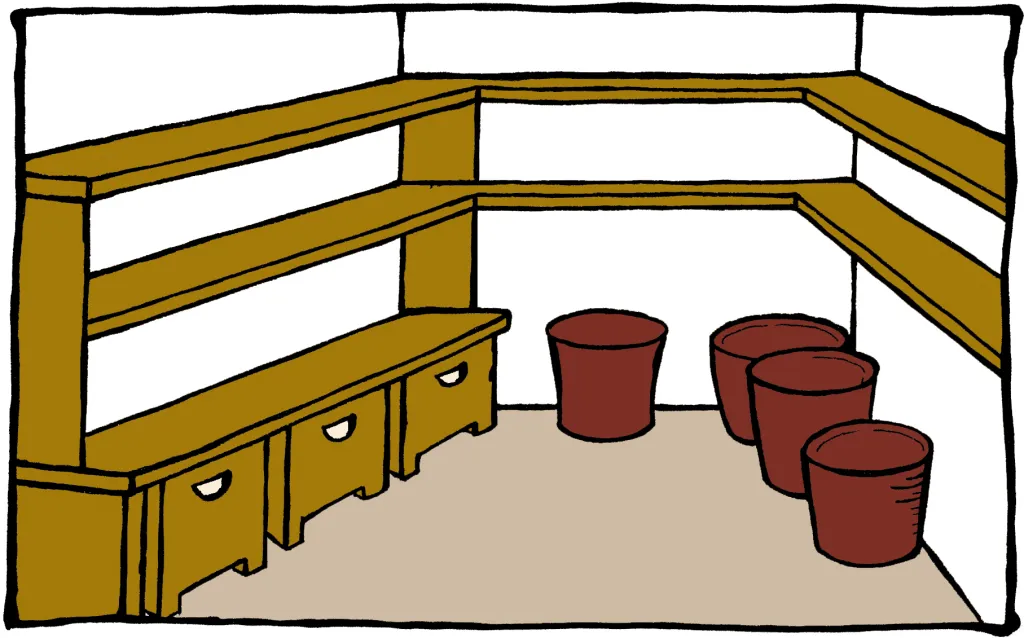

ice machine drain air gap companies

Best Practices for Air Gaps

1. Installation Guidelines When installing an ice machine, it's crucial to ensure that the drain line maintains an appropriate air gap. The gap typically has to be at least twice the diameter of the drain pipe, but specific requirements may vary based on local codes. It’s advisable to consult with local plumbing regulations or a professional plumber.

2. Regular Maintenance Checks Regular checks should be conducted to confirm that the air gap remains unobstructed and effective. This includes ensuring that the drain line is not clogged and that there are no installations that could override the air gap, such as additional plumbing fixtures.

3. Training Staff Training kitchen staff about the significance of the air gap and how to report potential issues can help maintain a safe environment. Employees should be educated on best practices, including proper cleaning of the area around the ice machine to prevent contamination.

4. Professional Inspections It is advisable for food service establishments to schedule periodic inspections with licensed plumbers who are knowledgeable about ice machine installation and maintenance. Experts can assess the system and make necessary adjustments to ensure compliance and safety.

5. Utilization of Quality Equipment When investing in ice machines, choosing equipment from reputable manufacturers who build in compliance with industry standards is crucial. Quality machines are more likely to incorporate features that promote safe drainage practices.

Conclusion

The air gap in ice machine drain systems is a simple yet vital aspect of food safety and equipment maintenance. By understanding its importance and adhering to best practices, food service establishments can provide safe and high-quality ice while adhering to necessary health regulations. Emphasizing the installation and maintenance of air gaps can lead to improved operational efficiency, sustainability, and, most importantly, customer safety. As the food service industry continues to evolve, staying updated on technology, plumbing codes, and equipment best practices is essential for ongoing success.