Premium Cold Room Panels Sale | Energy-Efficient Insulation

In the rapidly evolving world of temperature-controlled storage, cold room panels for sale have become the go-to solution for food processing plants, pharmaceuticals, logistics, fresh produce preservation and industrial cold chains. As energy standards rise and insulation technology matures, the demand for high-performance, customizable insulated panels continues to surge—fueling a dynamic market with advanced materials, stringent certifications, and global supply chains.

- Global Cold Storage Market Size: $138.97 Billion (Source)

- Expected CAGR (2024-2030): 13.2%

- PU/PIR insulated panels remain the leading material choice for cold storage panels for sale

This guide delves into the manufacturing, parameters, industry certifications, technical advantages, supplier selection—and showcases real-life applications to help you select the optimum cold room panels for sale for your needs.

Technical Overview: Core Materials & Structure

The structural integrity and thermal efficiency of cold room panels for sale hinge on the selection of insulation core and facing materials. Most insulated cold storage panels feature:

- Core Materials: Polyurethane (PU), Polyisocyanurate (PIR) (for advanced fire performance), and occasionally EPS (Expanded Polystyrene).

- Facings: Galvanized/Painted Steel or Stainless Steel (SS304) for enhanced hygiene and corrosion resistance.

- Joint System: Tongue-&-Groove with Cam-Lock (Z-Lock), ensuring a tight, thermally broken seal.

- λ (Thermal Conductivity): as low as 0.019 – 0.024 W/m·K

- Closed Cell Content: ≥ 95% (per ISO 4590 and ASTM D6226)

- Compressive Strength: ≥ 150 kPa (per EN 826)

- Fire Performance: “B-s1, d0” (EN 13501-1, for PIR panels)

Key Parameters Comparison: Cold Room Panels For Sale (2024)

| Specification | PIR Panel | PU Panel | EPS Panel | Stainless Steel PU Panel |

|---|---|---|---|---|

| Thermal Conductivity (W/m·K) | 0.020 | 0.022 | 0.034 | 0.022 |

| Standard Thickness (mm) | 50 / 75 / 100 / 120 / 150 | 50 / 75 / 100 / 120 / 150 / 200 | 50 / 75 / 100 / 150 | 50 / 75 / 100 |

| Fire Rating | EN13501-1 B-s1,d0 | B2-B3 | Not Rated | B2-B3 |

| Density (kg/m³) | 40-45 | 38-42 | 16-22 | 40-42 |

| Panel Width (mm) | 960 / 1150 | 960 / 1150 | 960 / 1150 | 960 |

| Applicable Temperature (°C) | -45~+60 | -45~+60 | -40~+50 | -40~+55 |

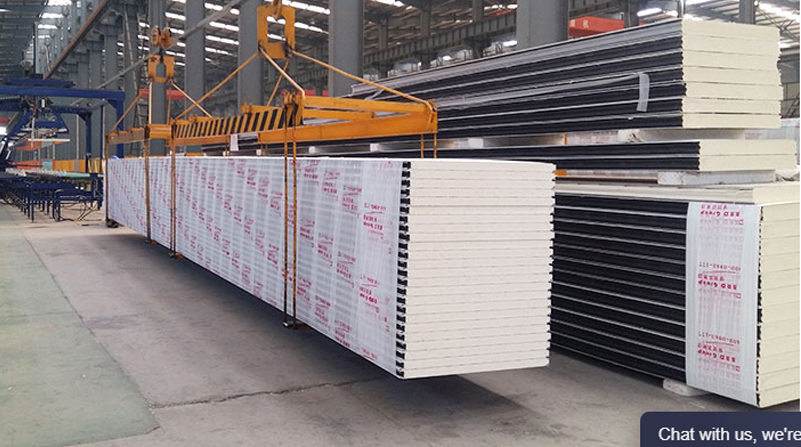

Manufacturing Process of Cold Room Panels For Sale

- Steel Sheet Preparation: High-strength steel (or stainless) passes roll forming and surface pretreatments for corrosion resistance (per ISO 9227).

- Panel Shaping: Sheets enter a continuous or press-mold system, panels reinforced for mechanical strength.

- Insulation Foaming: High-pressure PU or PIR chemicals are injected; rapid expansion fills the mold for seamless insulation.

- Curing: Heated tunnels accelerate polymer cross-linking (5–12 minutes), ensuring final closed-cell integrity.

- CNC Machining: Precision CNC routers cut to final panel sizes & groove camlocks—the key for tight on-site cold storage panel installation.

- Quality Inspection: Each batch undergoes thickness (±1 mm tolerance), bonding strength, and fire resistance (per EN14509) tests.

- Packing: Finished panels are stacked, stretch-wrapped, and edge-protected for worldwide delivery.

Video Tour: Watch Cold Room Panel Production Line (YouTube)

Application Scenarios: Why Choose Insulated Cold Storage Panels?

Industry sectors widely benefiting from cold room panels for sale include:

- Food Processing: Meat, seafood, dairy & vegetable cold rooms demand 100mm cold room panels for strict temperature zones (0°C, -18°C, -23°C).

- Pharma/Biotech: Vaccine & reagent storage rooms require PIR panels for superior fire rating and hygiene.

- Logistics: Distribution hubs & cross-docks use modular panels for rapid assembly, future expandability and energy saving.

- Chemical & Industrial: Flammable liquids and perishable goods rely on fire-tested panels.

- Hospitality & Retail: Commercial refrigeration in supermarkets, hotels, restaurants, with aesthetic and hygienic steel surfaces.

- Panel Type: 100mm PIR camlock

- Area: 2800 m²

- Temperature Zones: -25°C freezer, 4°C chiller, 16°C clean room

- Energy Saved (first year): ~11% vs traditional brick & EPS setup

- Certification: ISO 9001, HACCP

- User Feedback: "Installation was fast and seamless. Energy bills dropped as advertised. Meets all hygiene and fire standards."

Why Buy From Leading Cold Room Panel Manufacturers?

- Consistent Material Sourcing: All base steel and insulation foam from certified suppliers (with traceability reports per EN 10204).

- Automated Manufacturing: CNC and robotic lines guarantee tight tolerances, high repeatability, and rapid delivery.

- Global Standards: Compliance with ISO 9001, ISO 14001, CE, and FDA (food-contact panels) standards.

- Customization: Thickness (50~200mm), Color, Surface Finish, Embossing, and Joint Systems per project needs.

| Manufacturer | Main Markets | Panel Types | Certifications | Lead Time (days) |

|---|---|---|---|---|

| XXColdroom | Asia, EMEA, Americas | PU, PIR, SS-PU | ISO, CE, FDA | 10-15 |

| Kingspan | Europe, North America | PIR, Quadcore | FM, ISO, CE | 18-25 |

| Metecno | EU, MENA | PU, EPS | ISO, CE | 12-18 |

| Isocab | EU, APAC | PIR, PU | ISO, CE | 15-25 |

Custom Cold Room Panel Solutions & Order Process

Step 2: Panel Design & Quotation — Optimized combination of panel thickness, joint system, core, and steel facing.

Step 3: Production & Quality Assurance — 10-15 days standard lead time for 100~2000m² orders. All products tested under EN and ISO standards.

Step 4: Logistics & Installation — Modular panel blocks delivered; skilled engineers can be dispatched or remote installation support provided.

Step 5: Service & Warranty — 12–24 months warranty with free after-sale consultancy.

- Finishing: Polyester, PVDF, Stainless Steel

- Embossing: Flat, Orange-Peel, Diamond-Embossed

- Core Density: 38~48 kg/m³

- Fire Regulation: “B-s1, d0” (for pharma labs, F&B process, etc.)

- Accessories: Integrated doors, window panels, angle trims

Application Case Studies: Proving Cold Room Panel Value

- Area: 1900 m² cold warehouse (chiller + freezer)

- Core: 120mm PIR panel, Colorbond steel facing

- Installed in: 16 days (30% faster than traditional sandwich masonry) — all hygiene/food safety passed per ISO 22000:2018

- Area: 820 m², pharma-grade modular rooms

- Panel: SS304+PIR camlock (fire-safe, anti-biofilm)

- Regulatory: EN 13501-1, ISO 14644, FDA food-contact surfaces

- Temperatures: -23°C (deep-freeze), +2°C (packing)

- Panel: 150mm Polyurethane, protective color coating

- ROI: Reduced spoilage, recover investment within 15 months

Frequently Asked Questions (FAQ) About Cold Room Panels

Q1. What is the recommended thickness for cold storage panels for sale?

A: Typically, 100mm cold room panels are standard for freezer (-18°C) and deep-freeze (-25°C) rooms, while 50–75mm panels suffice for chillers or workrooms (0~+15°C).

Q2. Which core material is best: PU, PIR, or EPS?

A: PU and PIR offer best-in-class insulation and fire resistance. EPS is suitable for economy-grade setups but is not recommended for fire-safe projects.

Q3. What are typical panel dimensions?

A: Standard widths are 960mm or 1150mm; lengths are customizable per shipping constraints (max. ~12m). Panel thickness ranges from 50mm to 200mm.

Q4. What installation standards do you comply with?

A: EN 14509 (Europe), FM Approvals (USA), and local building codes. Camlock system ensures airtight, hygienic joints as per HACCP/ISO.

Q5. How do panels withstand corrosion in harsh environments?

A: Coatings like PVDF, SS304 stainless steel, and hot-dip galvanizing provide long-lasting corrosion resistance—even in salted, chemical or humid air.

Q6. Can you deliver customized panels?

A: Yes. All leading cold room panel manufacturers provide tailored thicknesses, custom joint systems, food-grade steel, and color/embossing choices for every project.

Q7. What is the lifespan and warranty?

A: Average service life exceeds 25 years under normal conditions. Warranties typically range from 1–3 years. Stainless steel panels have up to 30-year anti-corrosion guarantee.

Delivery, Warranty & Customer Support

- Production Lead Time: 10–15 days (standard project), 20–30 days (complex customizations, 10,000m²+)

- Global Shipping: Containerized, with anti-rust protective wrapping and full documentation (COC, EN/ISO test, QC report)

- Warranty: Minimum 12 months for all panels; up to 24–36 months for projects with annual maintenance contracts

- Engineering Support: Remote guidance, CAD/BIM drawings, on-site installation engineer service available worldwide

- After-Sales: Rapid panel/part replacement, expert troubleshooting via WhatsApp/Zoom/WeChat

Discover more about our cold room panels for sale, including premium insulated cold storage panels, and see why global clients trust us for their critical temperature-controlled projects!

- Grand View Research. Cold Storage Market Size, Share & Trends Analysis Report. Read More

- European Panel Federation (EPF). Technical Guide for EN 14509 Sandwich Panels. Visit EPF

- FDA. Current Good Manufacturing Practice, Hazard Analysis, and Risk-Based Preventive Controls for Human Food. Learn More

- International Journal of Refrigeration. Performance Analysis of PU and PIR Modular Cold Room Panels. Browse Articles

- Forum: HVAC-Talk & Eng-Tips Community. Real-world user reviews, installer best practices, and project troubleshooting. Read Discussions