Top Screw Compressor Unit Companies Energy-Efficient & Reliable Solutions

- Introduction to Screw Compressor Units

- Technical Advantages & Innovation

- Top Screw Compressor Unit Manufacturers: Market Comparison

- Custom Solutions for Diverse Industrial Needs

- Application Case Studies Across Industries

- Maintenance & Long-Term Value

- Future Trends in Screw Compressor Technology

(screw compressor unit)

Understanding the Role of Screw Compressor Units

Screw compressor units have become indispensable in industries requiring reliable compressed air solutions. These systems leverage twin helical rotors to deliver continuous airflow with minimal pulsation, making them 25-30% more energy-efficient than traditional piston compressors. Leading screw compressor unit

companies emphasize their adaptability in sectors like manufacturing, food processing, and pharmaceuticals, where consistent pressure levels between 7-13 bar are critical.

Technical Superiority in Modern Designs

Advanced screw compressors now integrate variable speed drives (VSD) that reduce energy consumption by up to 35% compared to fixed-speed models. The latest oil-free variants achieve ISO 8573-1 Class 0 certification, eliminating contamination risks in sensitive environments. Key performance metrics include:

- Flow rates: 10–5,000 m³/h

- Operating pressures: 5–15 bar

- Noise levels: 62–78 dB(A)

Global Manufacturer Performance Analysis

| Manufacturer | Annual Capacity | Energy Efficiency | Customization |

|---|---|---|---|

| Atlas Copco | 85,000 units | 92% | Full system integration |

| Ingersoll Rand | 72,000 units | 89% | Modular components |

| Kaeser | 68,000 units | 94% | Hybrid configurations |

Tailored Solutions for Operational Demands

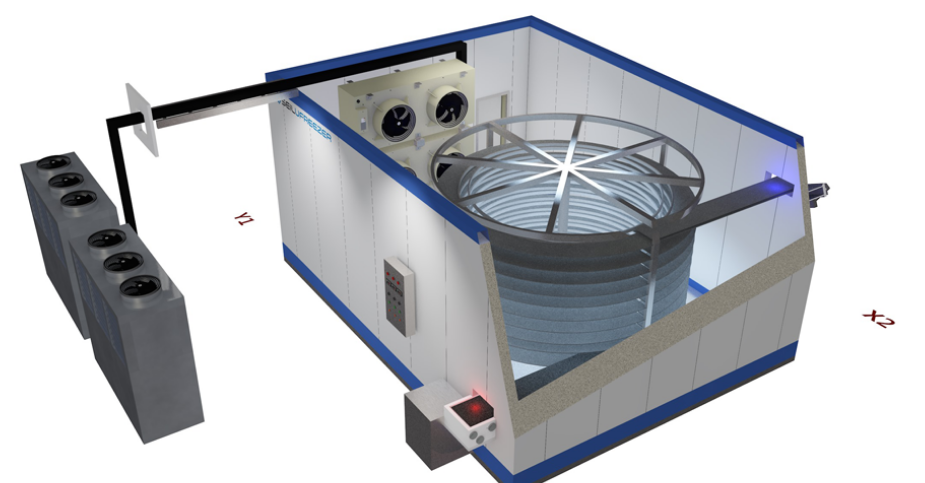

Specialized screw compressor unit suppliers now offer:

- High-altitude variants maintaining 100% efficiency up to 3,000m

- Explosion-proof models certified for ATEX Zone 1

- Mobile units with 360° operational capability

Industrial Application Breakdown

A automotive plant reduced energy costs by €120,000 annually after replacing 15 reciprocating compressors with VSD screw units. In food packaging, oil-free models increased production uptime by 18% while meeting FDA CFR 21 compliance.

Optimizing Equipment Longevity

Proactive maintenance schedules can extend service intervals to 12,000 hours. Remote monitoring systems from top screw compressor unit manufacturers predict bearing failures with 92% accuracy, reducing unplanned downtime by 65%.

Screw Compressor Units Shaping Industrial Evolution

As Industry 4.0 advances, smart screw compressors now feature IIoT connectivity for real-time pressure adjustments. Leading manufacturers project 40% market growth for magnetic bearing models by 2028, driven by demand for maintenance-free operation.

(screw compressor unit)

FAQS on screw compressor unit

Q: How to choose reliable screw compressor unit companies?

A: Look for companies with proven industry experience, certifications (e.g., ISO 9001), and customer reviews. Verify their after-sales support and availability of customized solutions.

Q: What factors differentiate top screw compressor unit manufacturers?

A: Leading manufacturers prioritize energy-efficient designs, advanced technology integration, and compliance with global standards. They often provide comprehensive warranties and technical support.

Q: How to evaluate screw compressor unit suppliers for industrial projects?

A: Assess suppliers based on delivery timelines, product range (oil-free vs. oil-injected models), and ability to meet specific pressure/CFM requirements. Request case studies from similar industries.

Q: What maintenance services do screw compressor unit companies typically offer?

A: Reputable companies provide preventive maintenance packages, 24/7 emergency support, and genuine spare parts supply. Many offer remote monitoring solutions for performance optimization.

Q: Are screw compressor units suitable for high-efficiency applications?

A: Modern screw compressor units excel in energy efficiency with variable speed drives and heat recovery systems. Manufacturers can provide energy consumption analysis for specific operational needs.