Screw Chiller Systems for Efficient Industrial Cooling Solutions

The Role of Screw Chiller Plants in Modern Industrial Applications

In today's rapidly evolving industrial landscape, maintaining optimal process temperatures is crucial for efficiency, safety, and product quality. Screw chiller plants have emerged as a pivotal solution to meet these demands across various sectors, including manufacturing, pharmaceuticals, and food and beverage production. This article delves into the features, benefits, and innovative applications of screw chiller plants, highlighting their significance in modern industrial operations.

Understanding Screw Chillers

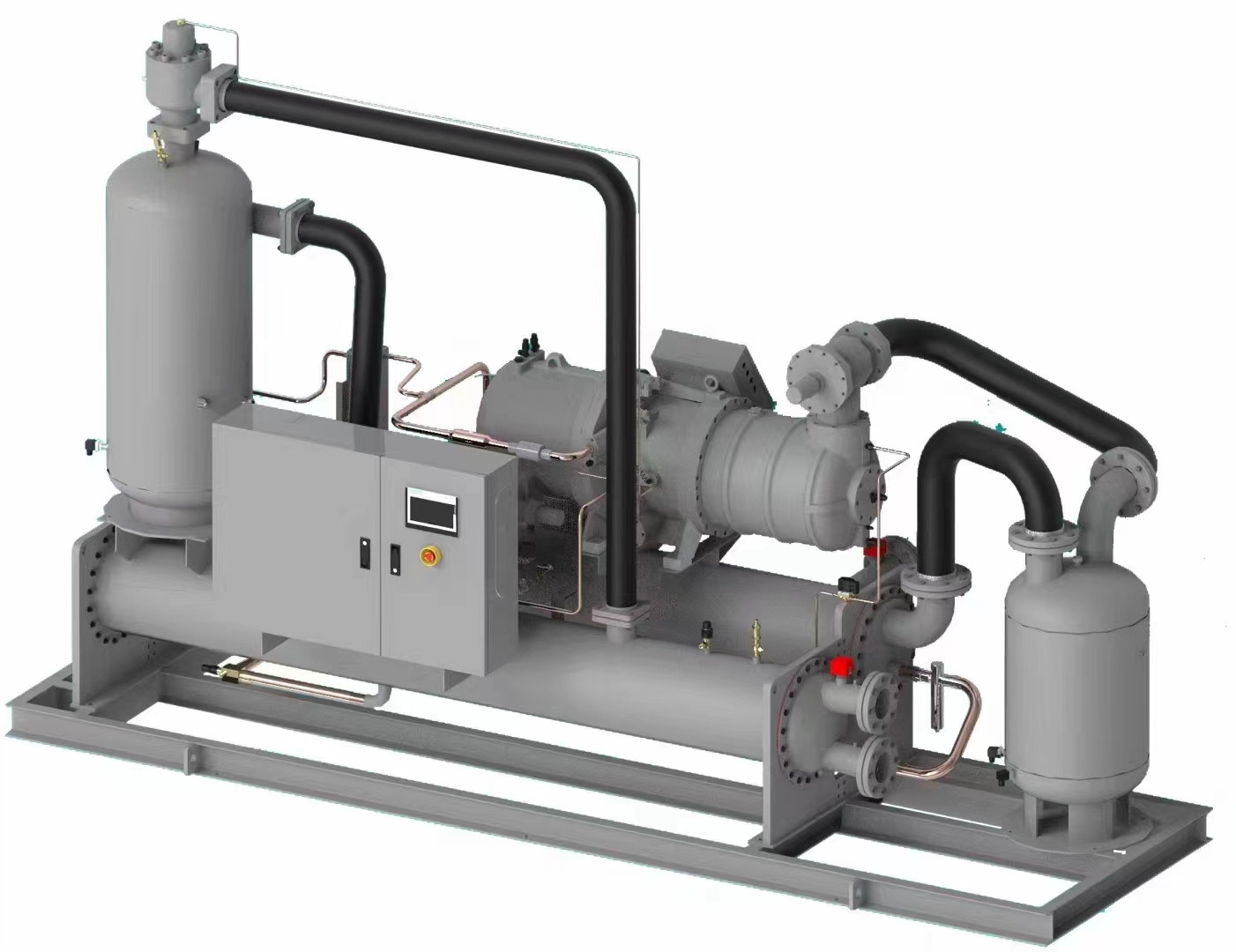

Screw chillers, named for their unique mechanism that utilizes twin-screw compressors, are a type of mechanical refrigeration system used to cool fluids. The fundamental principle behind their operation involves the absorption of heat from the process fluid and the subsequent release of that heat into the environment. This system primarily consists of a compressor, condenser, expansion valve, and evaporator.

The twin-screw design offers several advantages over traditional chiller systems. First and foremost, screw compressors are renowned for their efficiency and reliability. They can handle a wide range of capacities while maintaining a compact footprint, making them ideal for installations in space-constrained environments.

Efficiency and Energy Savings

One of the most compelling reasons for the increasing adoption of screw chiller plants is their energy efficiency. With rising energy costs and a growing emphasis on sustainability, industries are actively seeking technologies that reduce energy consumption. Screw chillers, equipped with advanced control systems and variable frequency drives, can optimize their operation based on real-time cooling demands. This adaptability not only lowers energy costs but also minimizes wear and tear on the equipment, extending the chiller’s lifespan.

Moreover, many modern screw chillers are designed with features like low global warming potential (GWP) refrigerants and enhanced heat exchangers

. These innovations further reduce the environmental impact and improve overall system performance, aligning with global efforts to mitigate climate change.Versatile Applications

screw chiller plant factories

Screw chiller plants are highly versatile and can be employed in various applications. In the manufacturing sector, they play a crucial role in process cooling, ensuring that machinery operates within optimal temperature ranges. This is especially important in industries such as plastics, textiles, and chemical processing, where excessive heat can adversely affect product quality and operational efficiency.

In the pharmaceutical industry, screw chiller plants are essential for maintaining the strict temperature controls required for sensitive products like vaccines and biologics. Any deviation in temperature can have serious implications for product integrity and patient safety, making reliable cooling systems vital.

The food and beverage industry also relies heavily on screw chillers. They are used for process cooling, ice production, and climate control in storage facilities. The ability to provide consistent and precise temperature control helps in preserving food quality and safety standards, thereby enhancing consumer trust.

Challenges and Considerations

While screw chiller plants offer numerous advantages, they are not without challenges. The initial investment for a high-quality screw chiller can be significant. Companies must carefully assess their cooling needs and operational requirements to ensure that the chosen system is both cost-effective and efficient in the long run.

Furthermore, as with any mechanical system, regular maintenance is crucial to ensure optimal performance and longevity. Neglecting maintenance can lead to failures, inefficiencies, and increased operational costs. Therefore, businesses must establish robust maintenance schedules and procedures.

Conclusion

Screw chiller plants are integral components of modern industrial operations, offering efficient cooling solutions across a wide range of applications. With their superior energy efficiency, reliability, and adaptability, these systems not only help businesses reduce operational costs but also contribute to sustainability efforts. As industries continue to evolve, the importance of effective cooling solutions will only increase, making screw chillers a vital asset for manufacturers committed to excellence and innovation. Investing in high-quality screw chiller technology is a step towards enhancing efficiency, ensuring product quality, and fostering a sustainable future in industrial operations.