मार्च . 05, 2025 03:09

Back to list

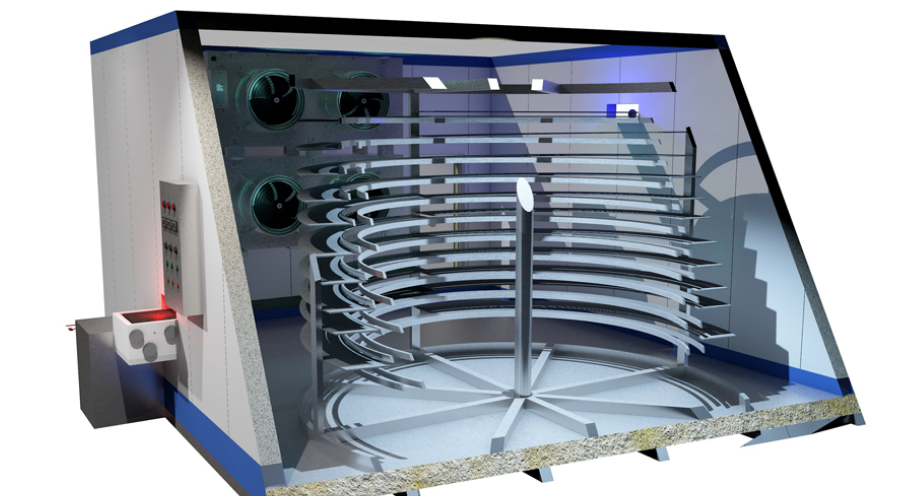

industrial air chiller

Industrial breweries and home brewing enthusiasts alike face the critical task of quickly cooling wort to prevent the growth of unwanted bacteria and ensure the perfect brew. The key to achieving this efficiently lies in investing in a high-quality industrial wort chiller. This essential piece of brewing equipment combines cutting-edge technology and robust design to provide optimal cooling performance, meeting the rigorous demands of any brewing setup.

The integration compatibility of a wort chiller with existing brewing systems is yet another aspect not to be overlooked. High-quality chillers come with standardized fittings and configurations, ensuring seamless compatibility with most industrial brewery setups. This includes compatibility with advanced brewing software and digital controls, enabling brewers to fine-tune their processes with precision and consistency, thereby enhancing product quality and operational efficiency. Safety features are integral to the design of any reliable industrial wort chiller. These chillers often include built-in safety mechanisms such as pressure relief valves, temperature sensors, and automatic shut-off features to prevent overheating or accidents, thereby protecting both the equipment and the operators. An emphasis on safety not only protects investments but also aligns with industry regulations and standards, further establishing the brewer’s credibility and commitment to quality. In the realm of industrial brewing, the return on investment for a high-quality wort chiller cannot be overstated. The initial expenditure is offset by the rapid cooling times, operational efficiencies, and the superior quality of the final product. By ensuring that the flavors and characteristics of the brew are preserved, industrial brewers can consistently meet consumer expectations, build brand reputation, and drive market success. Therefore, choosing the right industrial wort chiller is a decisive step towards enhancing brewing capabilities. It represents a commitment to excellence, marrying state-of-the-art engineering with practical brewing needs. This investment not only elevates the brewer’s craft but also secures a competitive edge in the bustling market of craft and microbreweries, underscoring a dedication to producing high-quality, consistent brews with every batch.

The integration compatibility of a wort chiller with existing brewing systems is yet another aspect not to be overlooked. High-quality chillers come with standardized fittings and configurations, ensuring seamless compatibility with most industrial brewery setups. This includes compatibility with advanced brewing software and digital controls, enabling brewers to fine-tune their processes with precision and consistency, thereby enhancing product quality and operational efficiency. Safety features are integral to the design of any reliable industrial wort chiller. These chillers often include built-in safety mechanisms such as pressure relief valves, temperature sensors, and automatic shut-off features to prevent overheating or accidents, thereby protecting both the equipment and the operators. An emphasis on safety not only protects investments but also aligns with industry regulations and standards, further establishing the brewer’s credibility and commitment to quality. In the realm of industrial brewing, the return on investment for a high-quality wort chiller cannot be overstated. The initial expenditure is offset by the rapid cooling times, operational efficiencies, and the superior quality of the final product. By ensuring that the flavors and characteristics of the brew are preserved, industrial brewers can consistently meet consumer expectations, build brand reputation, and drive market success. Therefore, choosing the right industrial wort chiller is a decisive step towards enhancing brewing capabilities. It represents a commitment to excellence, marrying state-of-the-art engineering with practical brewing needs. This investment not only elevates the brewer’s craft but also secures a competitive edge in the bustling market of craft and microbreweries, underscoring a dedication to producing high-quality, consistent brews with every batch.

Prev:

Next:

Related PRODUCTS

Copyright © 2025 Shijiazhuang Xuexiang Refrigeration Euquipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy