Stainless Belt Quick Freezer

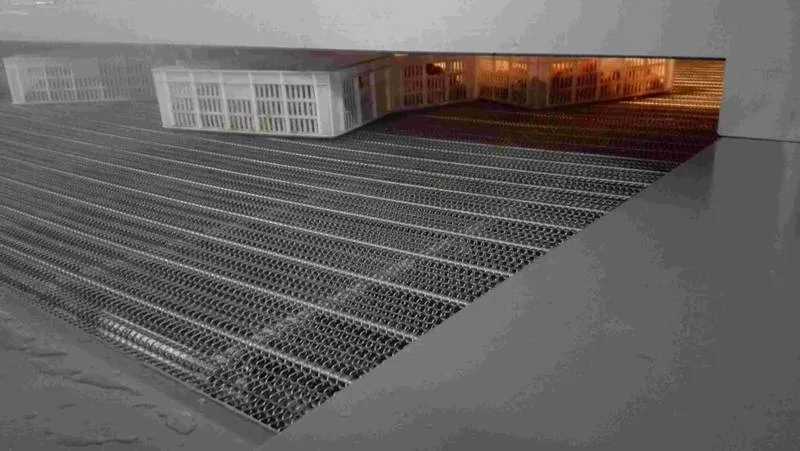

With the development of air blast cooling technology in the last few years,"high speed pulse"freezing is one of the moreeffective way to match the wind. When massive cooling air go through the even slits, it is accelerated to be the vertical cool airwith high speed, so the dynamic power between the slits forms the whirling air. Food moves forward along with the belt, andat the same time, both the vertical cooling and the whirling air act on both of the surface and the inner part of the product in arapid and constant way to gain high quality in the process of quick cooling.

This freezer is the best equipment for many kinds of product. Belt Freezer is mostly suitable for meat, seafood, fruit and vegetables, art factitious product.

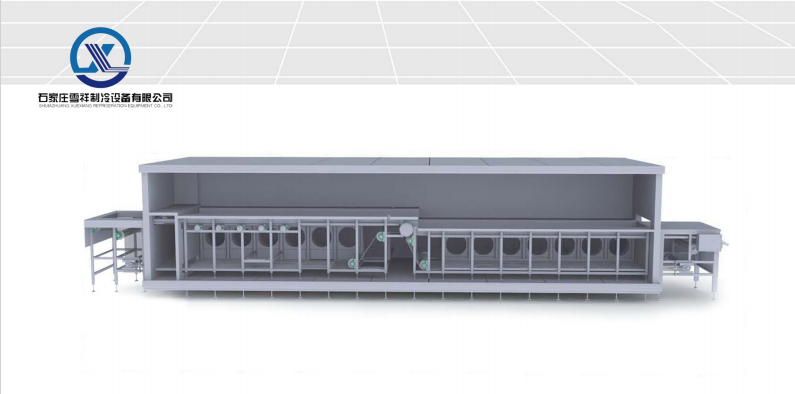

- 1.Pre-cooling keamer.

De pre-cooling keamer lit it iten te berikken in set freezing temperatuer yn tarieding op de wichtichste freezing sône. Pre-koelkeamers brûke typysk koelmiddelsirkulaasje en twongen fans om luchttemperatueren te ferminderjen en iten rap te koelen. Goede luchtstream en sirkulaasje ferminderet effektyf it temperatuerferskil en is de kaai foar it ferbetterjen fan snelfriesresultaten.

2. Items Inlet.

De ynlaat is it itenynputkanaal. Hjir ferpleatst it begeliedingsysteem fan 'e apparatuer it iten nei de wichtichste friessône fan' e tunnelfriezer. Troch dit proses, de ienheid soarget derfoar dat it iten komt yn 'e wichtichste freezing sône gelyk.

3. Main freezing sône.

De wichtichste frije sône is it haadgebiet dat de snelheid fan 'e masine fergruttet en it iten befriest. Hjir, it lucht systeem om de tunnel freezer soarget foar in koeling omjouwing foar it iten. Yn dit gebiet is de kuolsnelheid tige fluch en ferbetteret de freesmetoade sterk.

4. Items Outlet.

De outlet is it útfierkanaal foar it iten. Yn dit gebiet ferpleatst it liedingsysteem fan 'e apparatuer it beferzen iten út' e tunnelfriezer. Dit proses soarget foar itenyntegriteit en rappe befriezingseffisjinsje.

IQF Tunnel Freezer Applications

ㆍ Fluch befriezen en koeljen fan ferskate grienten en krûden

ㆍ Fluch befriezen en koeljen fan ferwurke seafood

ㆍ Fluch befriezen en koeljen fan ferskate ferwurke iten

ㆍ Fluch befriezen en koeljen fan fleis en ferwurke fleis

ㆍ Fluch befriezen en koeljen fan bôle, ryskoeke en dumplings

ㆍ Kin brûkt wurde om in protte soarten iten te produsearjen