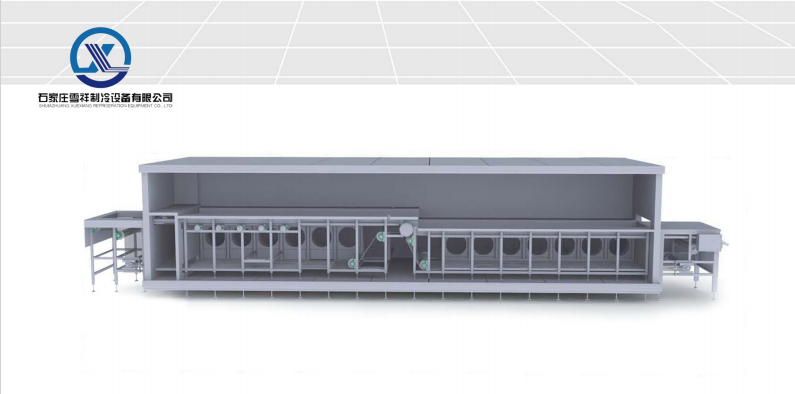

Tunnel Type Blast Freezer

Tunnel type quick freezer is a kind of equipment used for quick freezing of food. It consists of a series of cooling and conveyor belts. The food travels on the conveyor belts while being cooled by the freezing air that is wrapped around them. Food travels on these conveyor belts for a very short period of time, so it freezes the food quickly, bringing it to a safe temperature quickly, reducing the chance of bacterial growth while protecting the flavour and quality of the food.

-

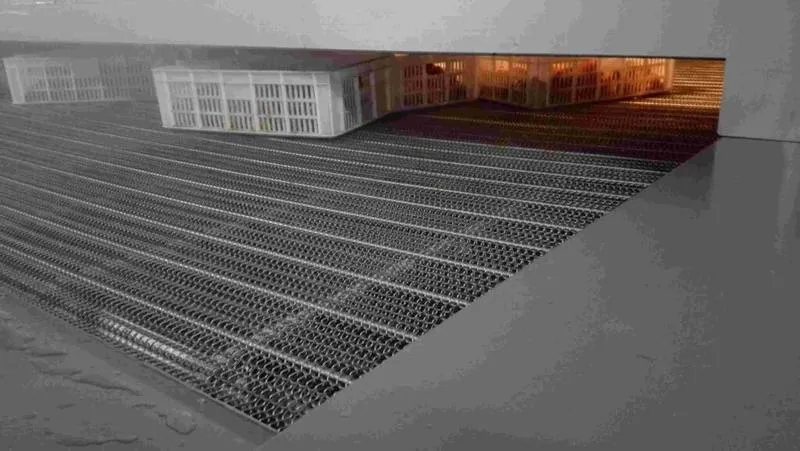

Mesh Belt Tunnel Freezer

Mesh Belt Tunnel Freezer has two kinds: stainless steel mesh and plastic steel mesh, the top and bottom can be ventilated, fast freezing speed, simple structure and long service life.

-

Plate Belt tunnel freezer

Plate Belt tunnel freezer adopts high-speed pulse air supply, and uses vertical cold airflow and vortex airflow alternately on the surface of the object, so that the surface of the object and the interior of the fast and continuous heat transfer

- 1.Pre-cooling chamber.

The pre-cooling chamber allows the food to reach a set freezing temperature in preparation for the main freezing zone. Pre-cooling chambers typically use coolant circulation and forced fans to reduce air temperatures and rapidly cool food. Good air flow and circulation effectively reduces the temperature difference and is the key to improving quick-freezing results.

2. Items Inlet.

The inlet is the food input channel. Here, the equipment's guidance system moves the food to the main freezing zone of the tunnel freezer. Through this process, the unit ensures that the food enters the main freezing zone evenly.

3. Main freezing zone.

The main freezing zone is the main area that increases the speed of the machine and freezes the food. Here, the air system surrounding the tunnel freezer provides a cooling environment for the food. In this area, the cooling rate is very fast and greatly improves the freezing method.

4. Items Outlet.

The outlet is the output channel for the food. In this area, the equipment's guiding system moves the frozen food out of the tunnel freezer. This process ensures food integrity and rapid freezing efficiency.

IQF Tunnel Freezer Applications

ㆍQuick freezing and cooling of various vegetables and condiments

ㆍQuick freezing and cooling of processed seafood

ㆍQuick freezing and cooling of various processed food

ㆍQuick freezing and cooling of meat and processed meat

ㆍQuick freezing and cooling of bread, rice cake and dumplings

ㆍCan be used to manufacture many kinds of food